Zero-VOC Waterborne Polyurethane Dispersions (PUD) play a vital role in the sustainable coatings industry, offering eco-friendly solutions tailored to stringent application and regulatory needs. These advanced PUD are engineered with diverse chemical architectures, categorized by their hard segment composition, particle size, and performance profile—including aliphatic and aromatic types, soft and hard segments derived from polyesters or polyethers, and those optimized for substrates like wood, plastic, and metal. Each PUD type brings unique characteristics such as superior mechanical robustness, excellent chemical resistance, and outstanding substrate adhesion that make it suitable for demanding, environmentally conscious coating applications.

Item No :

Waterborne PUDApplication :

Suitable for premium wood, flexible substrates, plastics, industrial metals, and printing inks.Special Feature :

Excellent zero-VOC, abrasion resistance, chemical resistance, adhesion, low-temperature film formation, and high gloss.Product Overview

Runshine New Materials (Foshan) Co., Ltd. manufactures a premium Zero-VOC Waterborne Polyurethane Dispersion (PUD), representing the forefront of sustainable coating technology. This advanced PUD is an aqueous colloidal system where urethane polymer chains are stabilized in water, enabling the formation of high-performance, eco-friendly films. The versatility of this PUD is demonstrated in its broad applicability, from wood and plastic to textile coatings, where it delivers exceptional mechanical properties, chemical resistance, and durability. As a cornerstone of modern coating formulations, this PUD provides a tailored solution for achieving superior performance while adhering to the most stringent global environmental regulations.

--------------占位---------------

Key Features

✧Exceptional Eco-Friendliness – This advanced PUD is formulated with zero volatile organic compounds (VOCs), ensuring compliance with the most stringent international environmental and safety regulations.

✧Superior Mechanical Durability – The unique polyurethane morphology within the PUD provides outstanding toughness, abrasion resistance, and scratch resistance, rivaling solvent-borne counterparts.

✧Excellent Chemical Resistance – A dense cross-linked network formed upon film formation offers robust resistance to solvents, oils, stains, and cleaning agents.

✧Outstanding Adhesion – This PUD exhibits excellent adhesion to a wide range of substrates, including wood, plastics, metals, and composites, without the need for primers.

✧Low-Temperature Film Formation – The designed polymer chemistry enables excellent coalescence at low temperatures, forming a continuous, high-performance film with minimal energy input.

✧High Elasticity & Flexibility – The molecular structure of the PUD provides exceptional flexibility and elongation, making it ideal for applications requiring bendability or dimensional movement.

✧Optical Clarity & High Gloss – The fine particle size and colloidal stability of this PUD allow for the formulation of crystal-clear coatings with excellent gloss development and depth of image.

✧Tailorable Rheology – The rheological profile of this waterborne PUD can be modified to enhance flow, leveling, and anti-sag properties for optimal application performance.

✧Thermal Stability – Coatings derived from this PUD maintain their integrity and performance under prolonged exposure to elevated temperatures.

✧Versatile Formulation Platform – This PUD is compatible with a wide range of additives and co-resins, enabling formulators to create tailored solutions for diverse coating applications.

| Parameter | Typical Value | Unit | Notes |

| Viscosity (25°C, Brookfield RV) | 200-20000 | mPa·s | Spindle 3, 20 rpm |

| Soild Content | (30-32)±1 | % | / |

| pH Value | 7.0-9.0 | – | / |

| Shelf Life | 12 | months | Stored in sealed containers at 5–35°C |

| Storage | Cool, dry place | – | Avoid direct sunlight and moisture |

| Zero-VOC Waterborne PUD Advanced Eco-Friendly Coating | ||||

| Model | Viscosity(mpa.s/25℃) | Soild Content % | pH Value | Character |

| RHERI®U200 | <1000 | 32±1 | 7.0-8.0 | Self-matting, good film-forming properties, scratch resistance and good adhesion to non-polar films. |

| RHERI®U202 | 500-2000 | 30±1 | 7.0-9.0 | Self-matting, low gloss, good online/offline printing transfer and leveling properties for offset printing machines. |

| RHERI®U222 | 500-2000 | 30±1 | 7.0-9.0 | Self-matting, low gloss, good online/offline printing transfer and leveling properties for offset printing machines. |

| RHERI®U226H | 200-1000 | 30±1 | 7.0-9.0 | Self-matting, good film-forming property, can be used in matte oil with various requirements. |

| RHERI®U303 | 200-2000 | 30±1 | 7.0-9.0 | Self-matting, extremely low gloss, and excellent thermal adhesion resistance. Can be used as blending resin for PVC building materials membranes to improve thermal lamination and adhesion problems. |

| RHERI®U3000 | 200-1000 | 31±1 | 7.0-9.0 | Self-matting and low gloss, can provide a pleasant hand-touch feeling and can absorbs sweat well. |

| For product list in detail ,kindly contact me for more | ||||

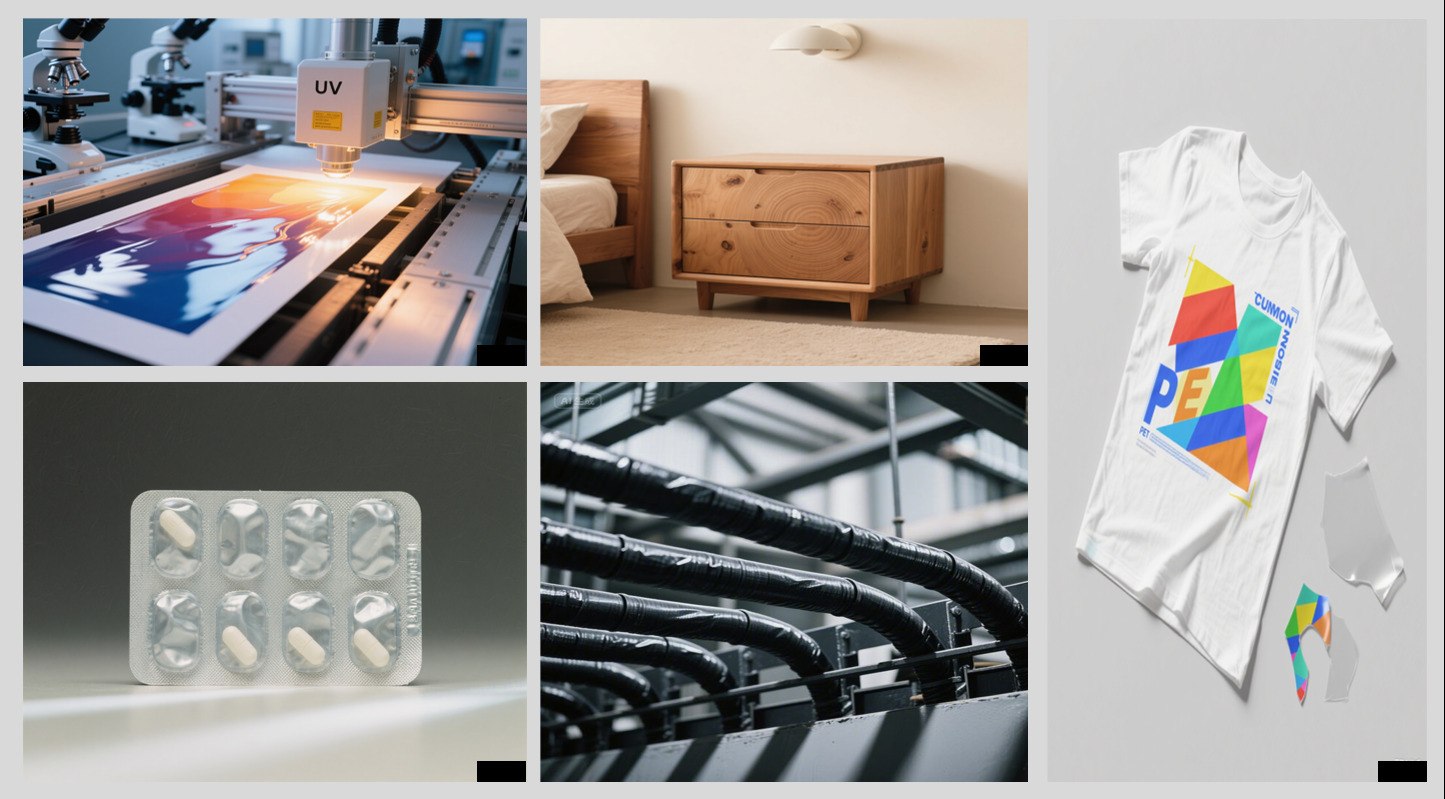

Applications

Our Zero-VOC Waterborne PUD Advanced Eco-Friendly Coating is engineered for high-performance, sustainable applications across diverse industries.

◊Premium Wood Coatings – For furniture, cabinetry, and flooring, providing exceptional clarity, abrasion resistance, and tactile feel.

◊Eco-Friendly Flexible Substrates – As a key component in coatings for synthetic leather, textiles, and PVC, offering superior flexibility and durability.

◊Plastic Substrate Coatings – Enhances adhesion and aesthetics on automotive interiors, consumer electronics, and household appliances.

◊High-Performance Industrial Coatings – Delivers corrosion resistance and weatherability for metal substrates in architectural and light-duty industrial applications.

◊Printing Inks & Overprint Varnishes – Provides low-VOC, high-wear resistance solutions for packaging and graphic arts.

Benefits

1. Environmental & Safety Excellence

Key Traits: Contains no volatile organic compounds (VOCs); water-based continuous phase; inherently sustainable

✧Primary Benefits:

Meets and exceeds global environmental regulations (e.g., EPA, REACH)

Reduces health and safety risks during application—low odor, non-flammable

Easily cleaned with water, minimizing solvent use and simplifying maintenance

✧Typical Uses:

Indoor wood and furniture coatings: This PUD provides a safe, healthy finish for residential and commercial interiors

Educational and healthcare furniture: The coating supports sustainability goals and ensures occupant safety

2. High-Performance Film Properties

Key Traits: Self-crosslinking or crosslinkable; nano-sized colloidal PUD particles; tunable hard/soft segments

✧Primary Benefits:

Delivers toughness, abrasion resistance, and chemical resistance comparable to solvent-based polyurethanes

Exhibits excellent hardness-to-flexibility balance—the PUD can be engineered for rigid or elastic films

Offers outstanding optical properties: high clarity, gloss, and depth of color

✧Typical Uses:

High-traffic flooring coatings: This PUD offers exceptional durability and stain resistance in eco-friendly formulations

Consumer electronics coatings: Delivers robust yet attractive surfaces for hand-held devices and accessories

3. Formulation Versatility & Processing Advantages

Key Traits: Broad compatibility with other aqueous resins; tunable rheology; coalesces at low temperatures

✧Primary Benefits:

Allows formulators to create hybrid systems (e.g., with acrylics) for customized cost-performance balance

The waterborne PUD enables easy application via spray, roll, or brush—adapts to existing manufacturing setups

Provides good storage stability, freeze-thaw resistance, and controllable drying profiles

✧Typical Uses:

Industrial and plastic coatings: This PUL formulation adheres well to diverse substrates while supporting low-VOC mandates

Automotive interior coatings: Used on dashboards, panels, and trim where low odor and high wear resistance are critical

4. Enhanced Substrate Compatibility & Adhesion

Key Traits: Designed with adhesion-promoting groups; fine particle size for excellent substrate wetting

✧Primary Benefits:

Achieves strong adhesion on difficult substrates (e.g., plastics, metals, wood) without primers

The PUD’s nano-scale particles penetrate porous surfaces, improving anchor and durability

Enables high-quality finishing even on heat-sensitive materials due to low curing temperatures

✧Typical Uses:

Packaging coatings: This PUD is applied as a film former or overprint varnish on paperboard and foil packaging

Textile and leather finishing: Imparts soft feel, abrasion resistance, and hydrolysis resistance without VOC emissions

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :