Polyester resin is a synthetic polymer made via polycondensation of polybasic acids and polyhydric alcohols. Runshine offers a range of Polyester resin for industrial coatings, including high molecular weight solid, saturated, and unsaturated variants, each tailored to specific coating needs.Key parameters of Polyester resin cover solid content, viscosity, hydroxyl value, acid value and density, all optimized for industrial coating performance.Recommended solvents for Polyester resin include xylene, ethyl acetate, butyl acetate and MEK. It cures with isocyanates or amino resins for 2-pack polyurethane and industrial coatings, and has a 12-month shelf life when stored sealed at 5–35°C in a cool, dry, sun and moisture-free environment.

Item No :

Polyester ResinApplication :

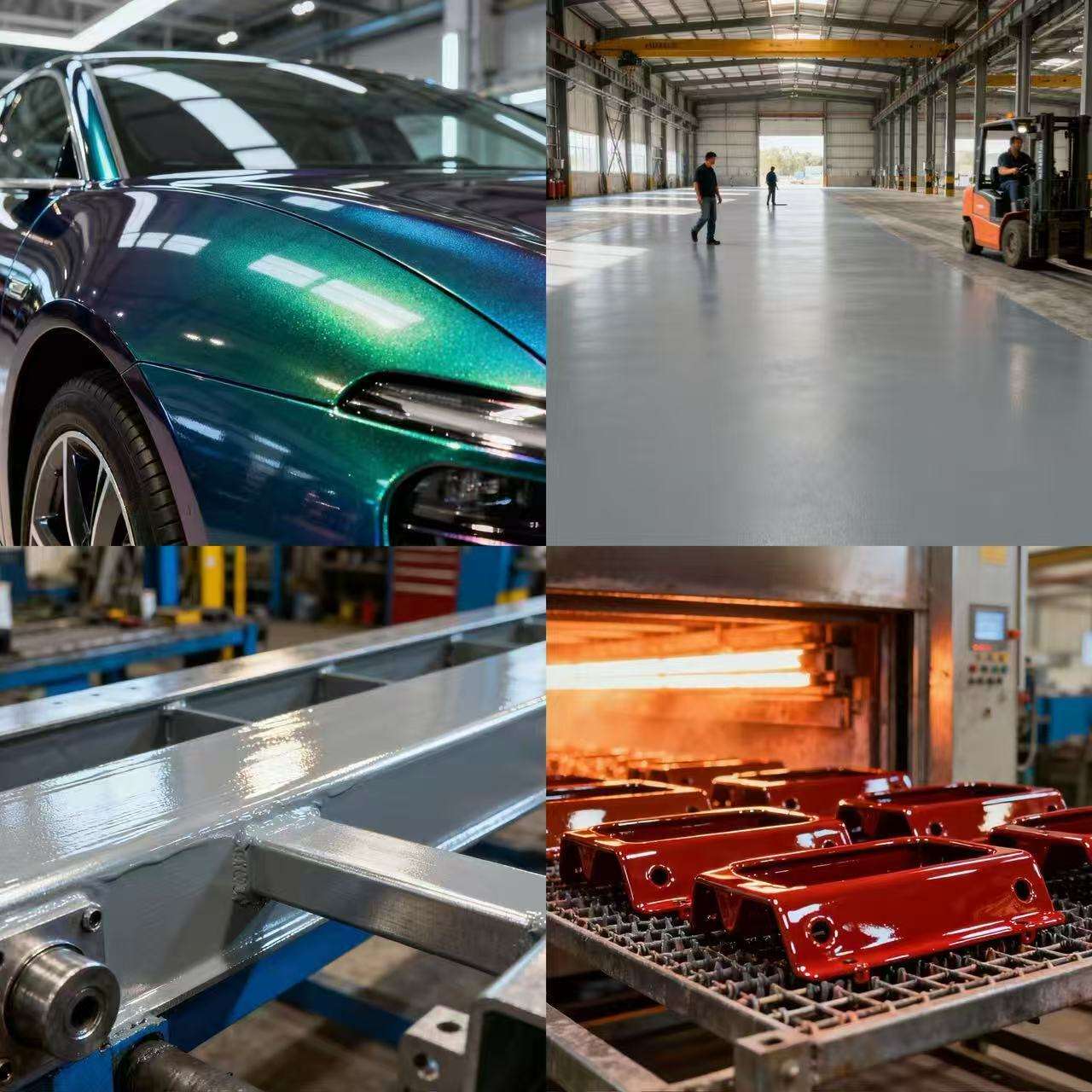

Polyester Resin is used in automotive, floor, metal surface and industrial baking enamel coatings.Special Feature :

Polyester Resin has good durability, chemical resistance, adhesion, processability and customizable properties.Product Overview

--------------占位---------------

Key Features

✧Excellent durability: Coatings made with Polyester resin resist abrasion, scratches, and minor impacts, ensuring industrial substrates remain intact even under harsh usage conditions for long periods.

✧Strong chemical resistance: Polyester resin shields industrial substrates from industrial chemicals, detergents, alcohol, and other common substances, preventing surface damage and preserving the functionality of coated products.

✧Superior adhesion and flexibility: The resin bonds firmly to diverse industrial substrates and accommodates slight expansion or contraction of substrates caused by temperature changes or external forces, avoiding coating cracking and maintaining long-term integrity.

✧Good processing performance: With excellent flow properties, Polyester resin can be smoothly applied via spraying, brushing, or rolling, ensuring uniform coverage on industrial substrates of varying shapes and sizes—critical for consistent coating quality in large-scale industrial production.

|

Parameter |

Typical Value |

Unit |

Notes |

|

Appearance |

Clear to pale yellow liquid |

– |

Visual inspection |

|

Solid Content |

40–100 |

% |

Can be adjusted for formulation |

|

Viscosity (25°C, Brookfield RV) |

15000–25000 |

mPa·s |

Spindle 3, 20 rpm |

|

Hydroxyl Value |

1.5–200 |

mg KOH/g |

Determines reactivity with curing agent |

|

Acid Value |

≤16 |

mg KOH/g |

Low acidity for stability |

|

Density (25°C) |

1.05–1.15 |

g/cm³ |

Typical value |

|

Glass Transition Temperature (Tg) |

-25–150 |

°C |

Affects hardness and flexibility |

|

Recommended Solvents |

Xylene, Ethyl Acetate, Butyl Acetate,MEK etc |

– |

For formulation compatibility |

|

Curing Method |

With isocyanates or amino resins |

– |

2-pack polyurethane or industrial coatings |

|

Shelf Life |

12 |

months |

Stored in sealed containers at 5–35°C |

|

Storage |

Cool, dry place |

– |

Avoid direct sunlight and moisture |

| High molecular weight polyester resin | |||||||||

| Product Name | Solid Content(%) | Tg(℃) | Mn | Visc. (cm3/g) | Structure | AV(Solids) OH | Value(Solids) | Solvent | Properties Application |

| RHEPOL1828 | 40 | 47 | 15000 | 500-1500 mpa.s |

L | 2 | 5 | S-100DBE | high molecular weight saturated poluesterresin,compatiblity,flexibilityalloy. |

| RHEPOL 1830 | 40 | 67 | 15000 | 3200-4800 mpa.s |

L | 4 | 5 | S-150/DBE | high molecular weight saturated poluester resin,high Tg and good compatibility. |

| RHEPOL 1860 | 100 | 105 | 15000 | 55 | L | 2 | 5 | good sterilization resistance,high adhesion | |

| RHEPOL1861 | 100 | 70 | 18000 | 56 | L | 2 | 6 | excellent flexibility and high hardness due toit's high Tg,good corrosion protection;co- binder to improve blockingresistance |

|

| RHEPOL1867 | 100 | 65 | 20000 | 70 | B | 6 | 6 | Excellent flexibility,high hardness,good substrate adhesion and corrosion protection; thinfilm primers |

|

| RHEPOL 1870 | 100 | 40 | 15000 | 64 | L | 2 | 5 | very flexible,high adhesion | |

| RHEPOL1871 | 100 | 40 | 20000 | 64 | B | 4 | 8 | Good reactivity,flexible,high adhesion, suitable as elastifying component | |

| RHEPOL1872 | 100 | 40 | 15000 | 62 | L | 4 | Highly flexible,high adhesion | ||

| RHEPOL1874 | 100 | -23 | 97 | opicdnisfalne povesiei fo themoplosic | |||||

| If need complete polyester resin brochure ,pls contact us |

|||||||||

| Saturated Polyester Resins | |||||||

| Product Name | Solid Content% | Solvent | Visc. | Colour | AV(Solids) | OH Value(Solids) | Properties Application |

| RHEPOL 1809 | 60 | S100/ S100/XYL |

U-W | ≤2 | ≤10 | Chemical resistance and water resistance,Automotive base coat,coloured coating and metallic base coatt | |

| RHEPOL 1853 | 70 | XYL |

≤3 | ≤7 | 80 | Stone-chipping resistance,adhesion,Automotive mid coat,aluminium paint and industrial baking enamel | |

| RHEPOL 1825 | 75 | S150 | 00-2 | ≤3 | ≤8 | 25 | Promote flexibility |

| RHEPOL 1835 | 100 | 3000-4000 | 00-2 | 156 | Formulate two-component coating compounds.Mainly used on concrete and asphalt floors and steel surfaces.Coatinas are touiah and flexible. hard-wearing and chemical-resistant. | ||

| RHEPOL1839 | 55 | MPA/S-100 | 2000-3000 | Max.5 | 72 | High Tg,Excellent chemical resistence. | |

| RHEPOL 1840 | 65 | S-150/BG | 1500-3500 | Max.3 | 36 | Excellent QUVresistance,Suitable for high durable paint. |

|

| If need complete Saturated polyester resin brochure ,pls contact us | |||||||

| Unsaturated polyester resin | ||||||

| Product Name | Solid Content % | Solvent | Visc. | Acid Number | Remarks | Properties Application |

| RHEUPE 1841 | 65 | Styrene |

550-700 | ≤15 | Amine pre- accelerated |

Non thixotropic resin for polyester putties |

| RHEUPE 1842 | 67 | Styrene |

700-900 | ≤15 | Resin addition for increasing elasticity |

|

| If need complete Unsaturated polyester resin brochure ,pls contact us | ||||||

Applications

✧Automotive coatings: Saturated polyester resins are used in automotive base coats, coloured coatings, metallic base coats, and mid coats, as well as in aluminium paints and industrial baking enamels. These applications provide robust protection and an attractive finish for automotive components, ensuring they withstand daily use and environmental exposure.

✧Floor coatings: High molecular weight polyester resins are formulated into two-component coating compounds for concrete and asphalt floors in industrial settings. These coatings are designed to handle high foot traffic and potential chemical contact, making them suitable for factories, warehouses, and other industrial facilities.

✧Metal surface coatings: Various types of Polyester resin (including saturated and high molecular weight variants) are applied to steel surfaces and aluminium materials in industrial environments. The coatings form a protective layer that resists corrosion, scratches, and impacts, extending the service life of metal components like machinery parts and structural elements.

✧Industrial baking enamels: Saturated polyester resins are integrated into industrial baking enamels, which are widely used to coat products such as household appliances, industrial machinery parts, and metal fixtures. These enamels provide a durable, heat-resistant finish that maintains performance under high-temperature conditions.

Benefits

✧Extends substrate service life: The protective layer formed by Polyester resin shields industrial substrates from moisture, UV rays, corrosion, physical damage, and chemical erosion, slowing aging and decay. This reduces the frequency of substrate replacement, lowering long-term costs for industrial enterprises.

✧Resists yellowing and discoloration: Even under long-term UV exposure and harsh industrial environments, Polyester resin maintains the original color and appearance of coatings. This eliminates the need for frequent repainting, reducing material consumption and maintenance efforts.

✧Offers moisture protection: For substrates like concrete floors and metal components in humid industrial environments, Polyester resin prevents moisture penetration. This avoids issues such as substrate warping, swelling, or rotting, ensuring the structural integrity and long-term performance of industrial facilities and products.

✧Enhances corrosion resistance: For metal substrates in industrial settings (such as steel machinery or aluminium fixtures), Polyester resin coatings form a barrier against rust and corrosion. This is particularly valuable in environments with high humidity, chemicals, or salt, extending the lifespan of metal components.

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :