This high-performance, styrene acrylic copolymer emulsion is engineered for formulating eco-friendly architectural coatings. It delivers excellent durability, adhesion, and scrub resistance, while complying with stringent international environmental standards through its low-VOC and APEO-free formulation. Ideal for sustainable interior and exterior paints.

Item No :

Water-based acrylate resinApplication :

Flexible packaging OPV coating and inkSpecial Feature :

Water-based and eco-friendly, versatile applications (sealing and barrier properties), no residue at high temperatures, excellent compatibility.Product Overview

Runshine New Materials (Foshan) Co., Ltd. offers a versatile APEO-free waterborne acrylic emulsion, engineered as a primary binder for eco-friendly architectural coatings. This polymer delivers durable films with tunable water resistance and excellent compatibility with additives like carbodiimide and polyurethane dispersions (PUD).Its adaptable properties allow for use in heat-seal coatings, matte varnishes, washable paints, and color pastes, supporting low-VOC formulations and compliance with international environmental standards.

--------------占位---------------

Key Features

✧ Exceptional ecological profile and regulatory compliance – Formulated as an APEO-free, water-based acrylic emulsion with minimal volatile organic compound (VOC) content, it complies with the most stringent international ecological regulations and sustainability goals, including REACH, EPA, and various eco-label standards for architectural coatings.

✧ Superior water and chemical resistance – The cured film exhibits outstanding resistance to water, chemicals, and blocking, ensuring long-lasting protection for interior and exterior architectural surfaces. Resistance properties can be finely tuned through neutralization with amines or ammonia of varying boiling points.

✧ Excellent formulation flexibility and compatibility – Demonstrates broad compatibility with other aqueous systems, including water-based polyurethane dispersions (PUDs). It can be blended to create economical matte coatings or used as a high-performance grinding resin for color pastes, ensuring uniform dispersion and stability.

✧ Versatile curing and application profiles – Water based acrylic resin can be air-dried or baked. When neutralized with sodium hydroxide (NaOH), it creates a water-washable temporary coating. After high-temperature curing, it decomposes cleanly without carbon residue, making it suitable for colored glass ceramic coatings.

✧ Optimized functional performance – Delivers excellent barrier properties and can be combined with carbodiimide crosslinkers for enhanced resistance. When blended with specific acrylic emulsions (e.g., 6037), it significantly improves low-temperature heat-seal strength for packaging-related applications.

|

Parameter |

Typical Value |

Unit |

Notes |

|

Appearance |

Colorless and transparent |

– |

Visual inspection |

|

Solid Content |

24-41 |

% |

Can be adjusted for formulation |

|

Viscosity (25°C, Brookfield RV) |

200-500CPS (25 ℃) |

mPa·s |

Spindle 3, 20 rpm |

|

Color |

<1 # (Fe-Co) |

/ |

/ |

|

Density (25°C) |

1.05–1.15 |

g/cm³ |

Typical value |

|

Recommended Solvents |

Water |

– |

For formulation compatibility |

|

Shelf Life |

12 |

months |

Stored in sealed containers at 5–35°C |

|

Storage |

Cool, dry place |

– |

Avoid direct sunlight and moisture |

| Water-based acrylic resin | |||||||

| Model | Type |

Tg(℃) | mfft(℃) | Viscosity(mpa.s/25℃) | Soild Content % | pH Value | Character |

| RHERI®A1303 | Water-based acrylic colloid liquid |

<7 | <500 | 40±1 | 7.0-8.0 | A water-based acrylic semi-colloidal solution. Can be combined with 6037 to improve low-temperature heat sealing fastness. Also have good barrier effect when combined alone with carbodiimide. | |

| RHERI®9020 | Water-based acrylic colloid liquid |

29 | 10 | <500 | 40±1 | 4.5-6.5 | An aqueous colloid that requires alkali neutralization. The water resistance and resolubility can be adjusted with ammonia and amines with different boiling points. Also can be neutralized with NaOH to make water-washable coating. After high-temperature baking and decomposition, there is no residual carbonized black matter, so it can be used as colored connecting material for glass ceramics. Also can be used as resin for grinding color paste. |

| RHERI®9025 | Water-based acrylic colloid liquid |

29 | 10 | <200 | 24±1 | 8.0-9.5 | A product of 9020 neutralized with ammonia. It has good compatibility with water-based polyurethane, can be used as economical matte oil when combined with water-based self-extinction PUD. |

| For more product list in detail ,pls feel free to contact us | |||||||

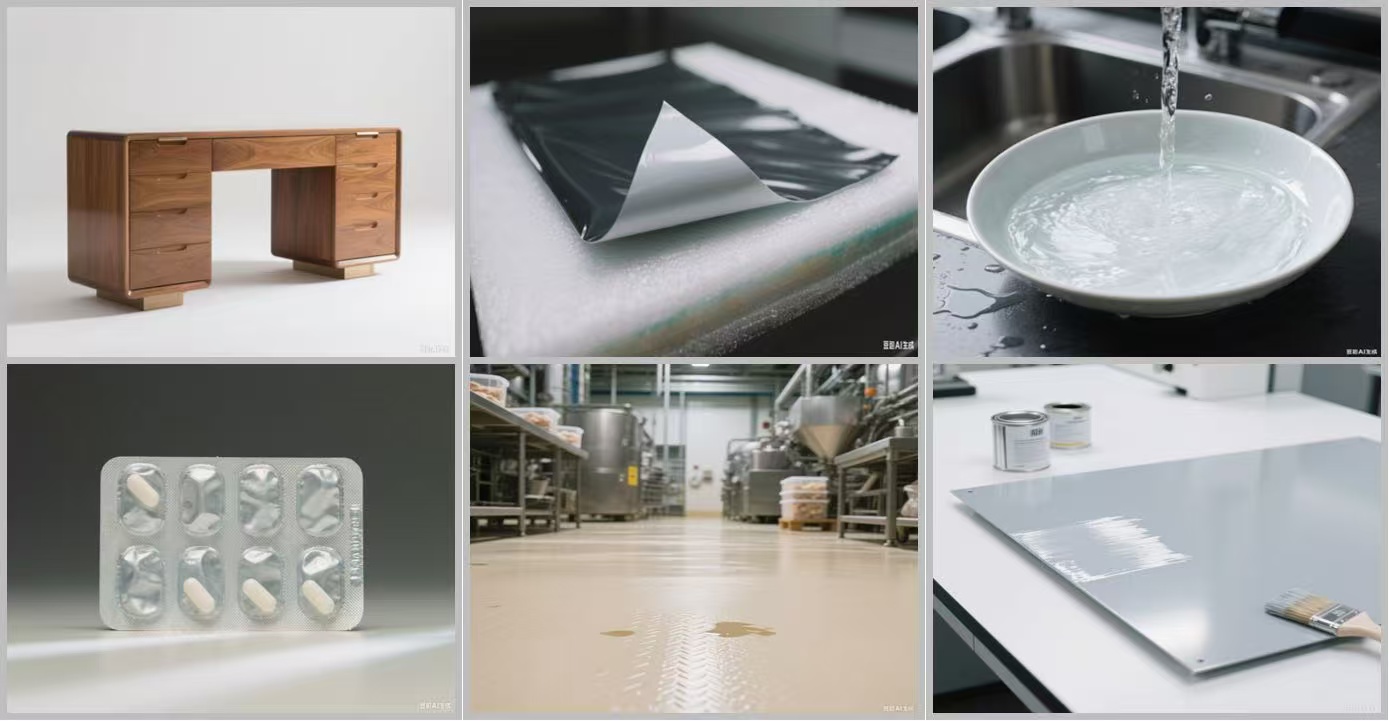

Applications

Our water-based acrylic emulsion is designed for advanced, eco-friendly coating systems requiring excellent film formation, barrier properties, and compatibility.

◊ Primer and topcoat formulations for metal substrates – offering corrosion resistance and adhesion

◊ Wear-resistant and chemical-resistant industrial flooring coatings

◊ Water-based barrier coatings for packaging materials (when combined with carbodiimide)

◊ Low-temperature heat-sealing coatings for flexible packaging (in combination with 6037)

◊ Water-washable coatings for glass and ceramics – leaves no residue after high-temperature baking

◊ Grinding resin for color pastes in industrial and decorative coatings

◊ Economical matte finishing agent for wood and plastic (when blended with water-based PUD)

Benefits

Water-Based Acrylic Emulsion For Surface Coatings

Key Traits: Alkali-soluble colloidal dispersion; requires neutralization for film formation; excellent compatibility with aqueous resins; leaves no residue upon thermal decomposition.

✧Primary Benefits:

Enables formulation of low-VOC, environmentally compliant coatings meeting stringent regulations.

Provides outstanding barrier properties and water resistance when crosslinked with carbodiimides.

Allows adjustable resolubility and curing profile through selection of neutralizing amines (e.g., ammonia, low-bp amines)

Ensures clean decomposition at high temperatures without carbon residue, ideal for demanding applications.

.

Serves as a highly economical modifier to enhance matting and compatibility in waterborne PU systems.

✧Typical Uses:

Glass & ceramic coatings: Used as a colored binder that burns out cleanly during high-temperature firing.

Wash-resistant coatings: Neutralized with NaOH to create coatings capable of withstanding aqueous cleaning.

Pigment grinding resin: Provides stable dispersion and compatibility for color paste formulations.

Matting agent for PU coatings: Blended with self-matting waterborne PUDs to create cost-effective matte finishes.

Barrier coatings for packaging: Combined with carbodiimide crosslinkers to improve low-temperature heat sealability and resistance properties.

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :