RHERI®U202T is solvent-free, anionic, aliphatic water-borne matte polyurethane resin dispersion engineered to deliver a deep matte, luxuriously soft-touch film without any matting powders or waxes. The dispersion forms coherent films at ambient or forced-dry conditions and is designed for high-end packaging, décor, leather, textile and specialty paper coatings

Item No :

RHERI®U202TApplication :

Various coating applications,such as film,textile, leather, plastic and paper coatingSpecial Feature :

Excellent soft-touch feeling and self -matting,Good adhesion to PVC/PET ,Blocking resistant ,Water boiling resistantProduct Description

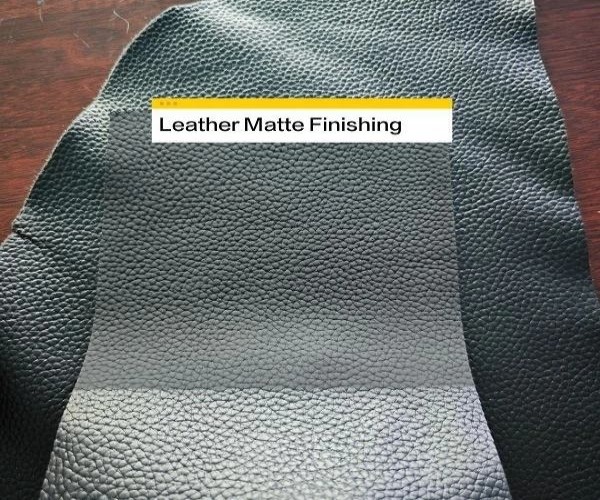

Water Based Matte Polyurethane is an resin designed for high-quality coating applications. With its excellent matte effect and outstanding abrasion resistance, this product is widely used in various industries. It is especially suitable for applications in the leather, textile, and automotive seat industries.s.When adding some curing agent (1-5%)like aziridine or polyisocyante hardener,the physical and chemical perfomrance will be improved better

Technical Data

| Apprearance | Milky white |

| Solid Content(%) | 30±1 |

| pH(25C°) | 7.0 - 9.0 |

| Viscosity(25C°,Mpa.s) | <1000 |

| Modulus(Mpa) | N/M |

| Elongation% | N/M |

| Tensile Srtrength(Mpa) | N/M |

Main Feature

Good adhesion to PVC/PET/OPP:

Water-based Polyurethane Dispersions for Gravure Printing of Flexible Packaging demonstrates excellent adhesion to common flexible packaging materials such as polyvinyl chloride (PVC), polyethylene terephthalate (PET) and oriented polypropylene (OPP). This strong adhesion ensures the durability and clarity of printed patterns on these substrates, and will not easily peel or fade even under long-term use or external stress.

Anti-blocking:

The water-based polyurethane dispersion has excellent anti-blocking properties, which effectively prevents damage caused by adhesion of printed films during stacking or winding. This feature is crucial to ensure efficient production and high-quality finished products, especially in high-volume industrial environments, where it reduces production failures and defective rates.

Excellent compatibility with alcohol:

Water-based Polyurethane Dispersions for Gravure Printing of Flexible Packaging has excellent compatibile

Application

Water-based Polyurethane Dispersions for Gravure Printing of Flexible Packaging is a reverse gravure printing ink specially developed to meet the needs of the flexible packaging industry. It provides a perfect printing solution for various types of soft materials, from daily consumer goods to high-end brand packaging, and can achieve

Storage&Remarks

waterborne polyurethane binder are stable when stored at 20°C for 6 months after delivery date. The recommended temperature range is 5~30 oC. Freezing or storage at higher temperature than 30°C, can affect the viscosity or the average particle size and finally lead to a sedimentation or coagulation. A contamination with bacteria, fungi or algae can damage the product irreversible

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :