Excellent Oxygen-barrier and Water-resistant Waterborne Polyurethane Dispersions on Metallized PET Films.

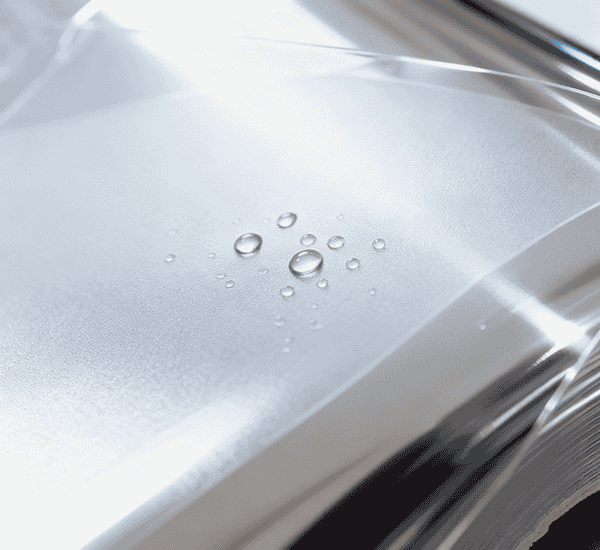

Excellent Oxygen-barrier and Water-resistant Waterborne Polyurethane Dispersions have emerged as a critical technology for advanced packaging applications on metallized PET films, addressing the stringent demands for high-performance barrier coatings in industries such as food and pharmaceuticals. These specialized Waterborne Polyurethane Dispersions are engineered through precise molecular design to form a uniform, durable film that provides exceptional resistance to oxygen permeation and water ingress, ensuring long-term protection of sensitive contents.

Item No :

Waterborne Polyurethane DispersionsApplication :

Metallized PET FilmsSpecial Feature :

Excellent Oxygen-barrier and Water-resistantProduct Overview

Excellent Oxygen-barrier and Water-resistant Waterborne Polyurethane Dispersions for Metallized PET Films represent a state-of-the-art coating technology engineered to deliver superior functional barrier properties for high-performance packaging applications. These advanced Waterborne Polyurethane Dispersions are specifically formulated for excellent adhesion to metallized PET substrates, forming a tough, continuous, and crosslinked film that provides an exceptional barrier against oxygen transmission and liquid water penetration. This specialized Waterborne Polyurethane Dispersions technology integrates seamlessly into industrial coating processes, offering a reliable and efficient solution to enhance the protective performance of packaging structures without compromising their recyclability. It directly addresses the critical industry demands for extending product shelf-life and protecting sensitive contents, enabling packaging that reliably resists gas and moisture while fully complying with global food-contact and environmental regulations for safe and sustainable solutions.

--------------占位---------------

Key Features

◊ Exceptional Oxygen and Water Vapor Barrier Performance:

These Waterborne Polyurethane Dispersions are molecularly engineered to form a dense, cohesive film upon drying and curing. The unique polymer architecture, characterized by a high degree of hydrogen bonding and potential for crosslinking, creates a tortuous path for gas molecules. This results in an excellent oxygen barrier, critically extending the shelf-life of sensitive products like food and pharmaceuticals on metallized PET film substrates. The film's inherent hydrophobicity further ensures outstanding resistance to water vapor transmission.

◊ Superior Adhesion and Metallized Film Compatibility:

This specific grade of Waterborne Polyurethane Dispersions is formulated for optimal adhesion to non-porous, low-surface-energy surfaces like metallized PET. The dispersion's chemistry promotes strong anchorage to the metal layer, preventing delamination or film lifting during subsequent processing or end-use flexing. This robust interfacial bond is fundamental to maintaining the integrity of the overall barrier structure.

◊ Environmental Compliance and Processing Advantages:

As a water-based system, these dispersions significantly reduce VOC emissions compared to solvent-borne alternatives, aligning with global environmental and workplace safety regulations. They are designed to be free of heavy metals and other regulated substances, making them suitable for demanding food-contact packaging applications. Furthermore, these Waterborne Polyurethane Dispersions offer excellent mechanical stability and are compatible with standard industrial coating techniques, ensuring reliable performance in high-speed production environments.

◊ Durability and Functional Integrity:

The cured film from this polyurethane dispersion exhibits remarkable toughness, abrasion resistance, and flexibility. It protects the delicate metallized layer from scratches and cracks that could compromise barrier properties. This durability ensures that the packaging maintains its excellent oxygen and water resistance throughout the supply chain, even under mechanical stress, guaranteeing consistent protection for the packaged contents.

|

Parameter |

Typical Value |

Unit |

Notes |

|

Appearance |

Milky white |

– |

Visual inspection |

|

Solid Content |

32±1.5 |

% |

Can be adjusted for formulation |

|

Viscosity (25°C, Brookfield RV) |

<500 |

mPa·s |

Spindle 3, 20 rpm |

|

pH-value (25°C) pH |

7.0 - 9.0 |

/ |

/ |

|

MFFT(°C) |

Approximately 7 ℃ |

℃ |

Typical value |

|

Recommended Solvents |

- |

– |

For formulation compatibility |

|

Shelf Life |

6 |

months |

Stored in sealed containers at 5–30°C |

|

Storage |

Cool, dry place |

– |

Avoid direct sunlight and moisture |

Applications

The application of Excellent Oxygen-barrier and Water-resistant Waterborne Polyurethane Dispersions on metallized PET films is a sophisticated process designed to maximize the protective functionality of high-performance packaging. The following outlines the critical steps to ensure optimal barrier performance.

◊ Substrate Preparation and Priming:

The metallized PET film substrate must be meticulously cleaned to remove any surface contaminants that could impede adhesion. While the surface energy of PET is generally suitable, a specific grade of these Waterborne Polyurethane Dispersions is formulated with adhesion-promoting chemistries that create a strong physico-chemical bond with the metallized layer. This step is fundamental to establishing a foundation for a continuous, defect-free barrier film that will not delaminate.

◊ Coating Application and Metering:

This high-performance Waterborne Polyurethane Dispersions is engineered for compatibility with precision coating techniques such as micro-gravure or slot-die coating. These methods are ideal for applying an ultra-thin, uniform layer onto the non-porous metallized PET surface. Precise control over the coat weight is critical to achieving the target oxygen transmission rate (OTR) and water vapor transmission rate (WVTR) without negatively impacting the optical clarity or flexibility of the final laminate structure.

◊ Drying, Coalescence, and Film Formation:

Following application, the coated web enters a multi-stage drying oven. Under controlled temperature and airflow, water is evaporated, allowing the polyurethane particles to pack closely. Subsequently, these particles coalesce (fuse) and form a continuous, dense film. The film formation mechanism of these dispersions is key to developing a pinhole-free layer with an intrinsically tortuous path for gas molecules, which is the origin of the excellent oxygen-barrier property.

◊ Post-Treatment (Curing) for Performance Enhancement:

To fully develop the ultimate barrier resistance and chemical durability, a post-treatment thermal curing stage is often employed. This process facilitates the completion of any designed cross-linking reactions within the polyurethane matrix. The resulting increase in molecular weight and cross-link density significantly enhances the film's cohesion, chemical resistance, and long-term stability, ensuring the barrier integrity is maintained under humid conditions and throughout the packaging's shelf life.

Benefits

Achieve Unmatched Barrier Protection for Sensitive Products: The advanced formulation of these Waterborne Polyurethane Dispersions creates a dense, cohesive film with a highly cross-linked molecular structure upon curing. This engineered polymer network presents an exceptionally tortuous path, forming an impervious barrier that effectively blocks oxygen permeation and resists water vapor transmission. This significantly extends the shelf life of oxygen-sensitive contents like roasted snacks, pharmaceuticals, and premium foods packaged on metallized PET films, ensuring product freshness and integrity.

Ensure Full Regulatory Compliance and Safety for Demanding Applications: As a purposefully formulated, water-based system, these dispersions are designed to be free of heavy metals, phthalates, and other regulated substances. The use of these Waterborne Polyurethane Dispersions simplifies compliance with stringent global food-contact and safety regulations (e.g., FDA, EU No. 10/2011), mitigating migration risks and enhancing brand trust for consumer packaging.

Streamline Production with Excellent Coating Processability: Engineered for high-speed precision coating operations such as gravure and slot-die, this specific grade of Waterborne Polyurethane Dispersions offers outstanding stability and runnability. It provides excellent wetting and adhesion to challenging metallized PET surfaces, ensuring uniform coverage and efficient, trouble-free production with minimal downtime, leading to higher line efficiency and yield.

Uphold Sustainability Values with High-Performance Chemistry: This eco-friendly dispersion technology aligns with modern environmental goals. Its water-borne nature ensures low VOC emissions, contributing to a safer workplace and reduced environmental impact. Furthermore, the ultra-thin, high-efficiency barrier provided by the polyurethane film facilitates the creation of recyclable packaging structures, allowing brands to meet their sustainability targets without compromising the critical high-barrier performance required for premium packaging.

Enhance Final Package Durability with a Robust Functional Coating: The cured film from this dispersion is not only a high-performance barrier but also exhibits remarkable toughness, abrasion resistance, and flexibility. It effectively protects the delicate metallized layer from scratches and cracks during conversion and throughout the supply chain, ensuring the packaging maintains its superior appearance and, most importantly, its barrier integrity from production to end-use.

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :