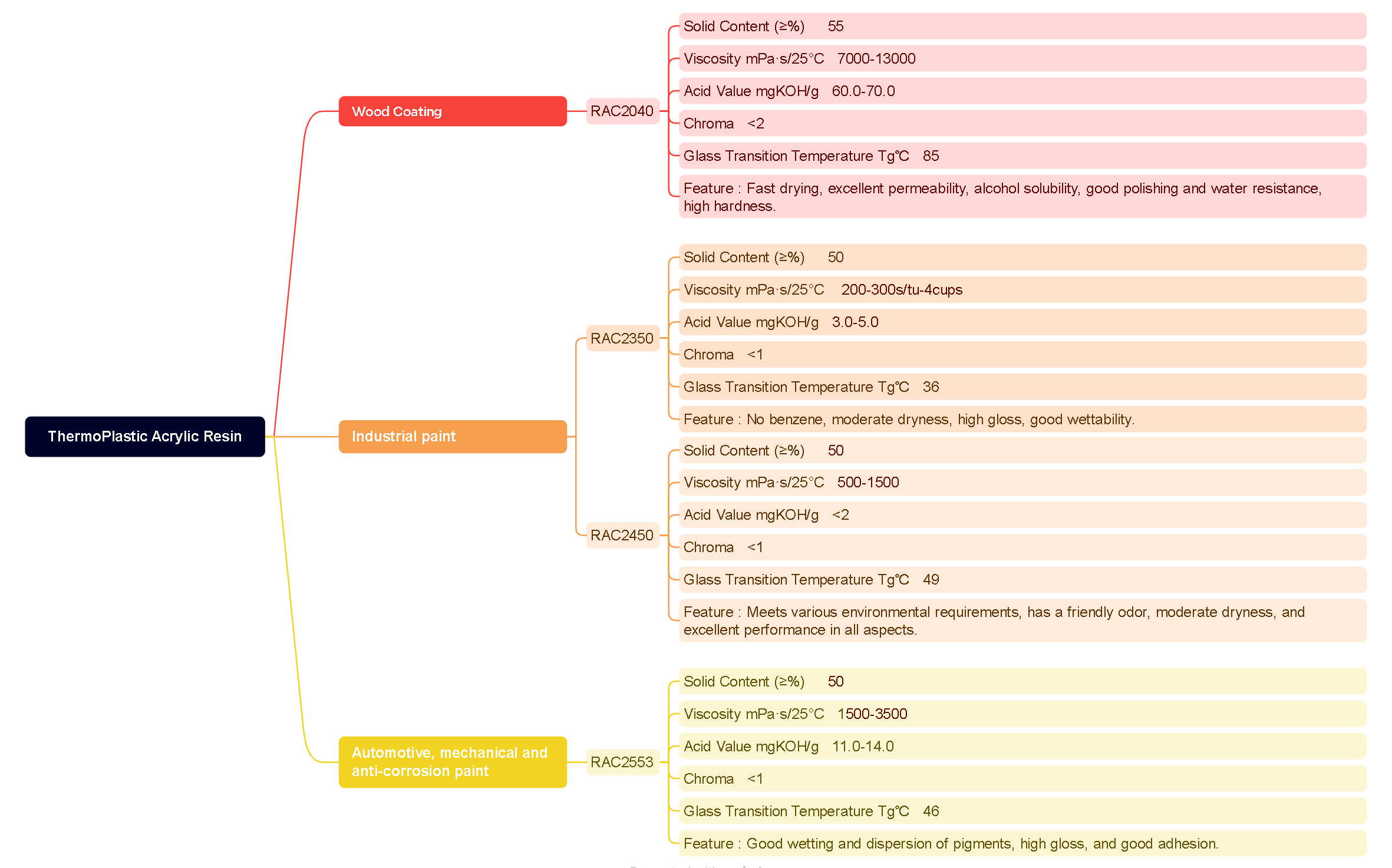

The thermoplastic acrylic resin products are designed to meet the diverse needs of the industrial coating industry. These resins are formulated with high - quality monomers, offering a range of properties that make them suitable for various applications, especially in industrial, automotive machinery, and anti - corrosion coatings, as well as in wood coatings.

Item No :

Thermalplastic acrylic resinApplication :

.Industrial, automotive, wood coatings.Special Feature :

Fast drying, good hardness, high gloss, etcProduct Overview

Thermoplastic acrylic resins are linear polymers formed by the polymerization of monomers such as acrylic acid, methacrylic acid, and their esters, nitriles, and amide derivatives. They exhibit the characteristic of softening upon heating and solidifying upon cooling. In the context of industrial coatings, these resins play a crucial role in determining the performance of the final paint products—whether for industrial equipment, automotive machinery parts, or anti - corrosion protection, their inherent properties directly enhance the reliability and longevity of the coated surfaces.

--------------占位---------------

Key Features

◊ Outstanding Physical and Mechanical Properties: Provide good hardness, flexibility, and toughness to coatings, ensuring durability that meets the high demands of industrial use, automotive machinery operation, and anti - corrosion scenarios.

◊ Excellent Weather Resistance: Resist the degradation caused by sunlight, rain, and temperature changes, maintaining the appearance and performance of industrial coatings, automotive machinery coatings, and anti - corrosion coatings over time.

◊ Good Chemical Resistance: Withstand exposure to various chemicals, acids, and alkalis, making them suitable for harsh environments where industrial equipment and automotive machinery often operate, and critical for long - term anti - corrosion protection.

◊ High Gloss and Color Retention: Contribute to coatings with high - gloss finishes and excellent color stability, enhancing the aesthetic appeal of coated industrial equipment, automotive machinery parts, and even wooden surfaces.

◊ Compatibility: Demonstrate good compatibility with other resins such as nitrocellulose, allowing for the formulation of customized coatings that better adapt to the specific needs of industrial, automotive machinery, anti - corrosion, and wood coating applications.

| Parameter | Typical Value | Unit | Notes |

| Viscosity (25°C, Brookfield RV) | 50-55 | mPa·s | Spindle 3, 20 rpm |

| Acid Value | 3.0-70.0 | mgKOH/g | / |

|

Viscosity

|

500-13000 |

mPa·s/25°C

|

/ |

| Chroma | <2 | – | / |

| Shelf Life | 12 | months | Stored in sealed containers at 5–35°C |

| Storage | Cool, dry place | – | Avoid direct sunlight and moisture |

Applications

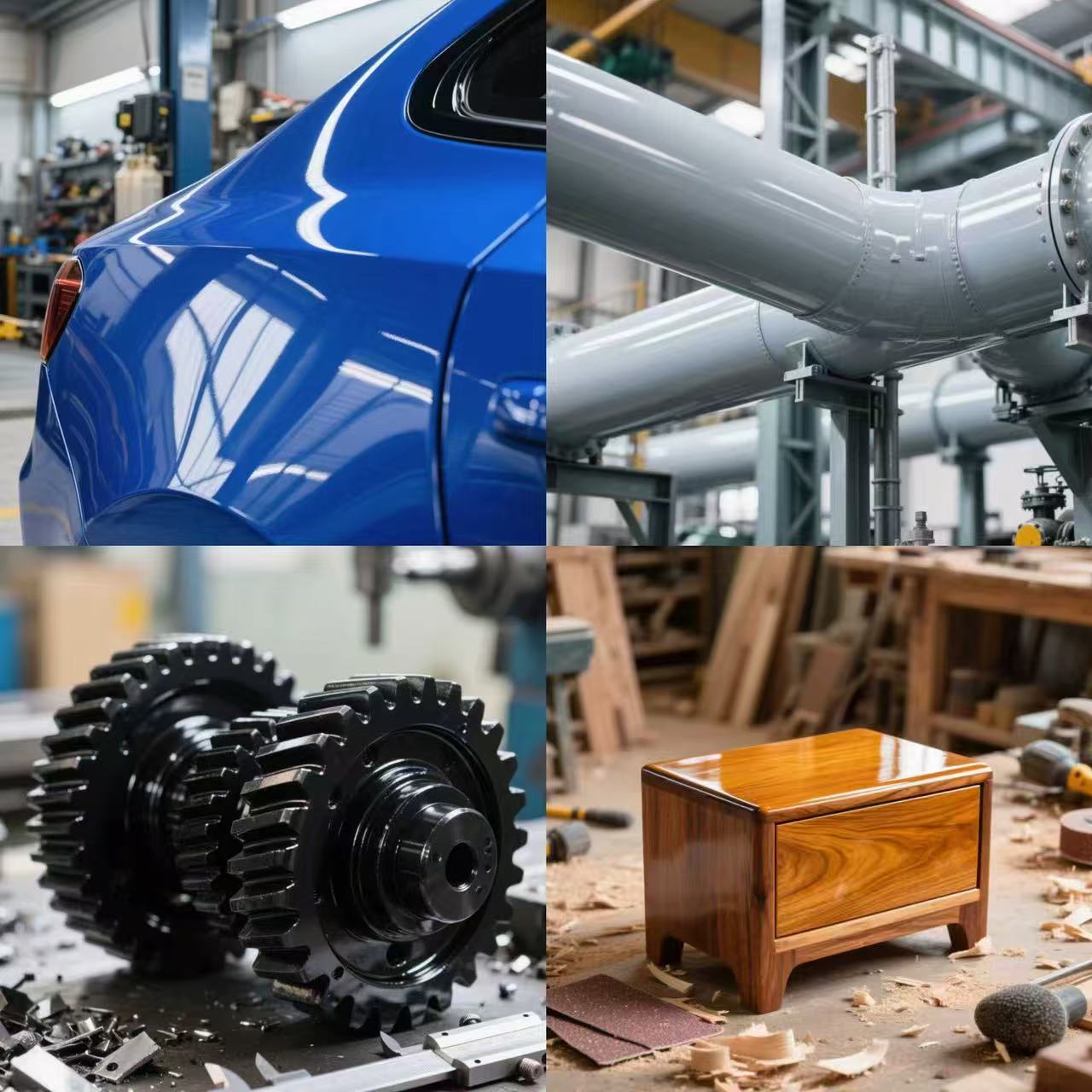

◊ Used in coatings for industrial equipment (such as pumps, valves, and production lines), providing reliable protection against corrosion, wear, and chemical exposure in factory environments.

◊ Ideal for coating metal parts in factories (including brackets, housings, and transmission components), ensuring long - term durability and stable performance under continuous operation.:

◊ Applied to automotive parts (including engine components, body frames, and chassis), forming a robust barrier against rust and corrosion caused by road salts, moisture, and engine fluids.

◊ Used in machinery coatings (for construction machinery, agricultural machinery, and industrial robots), enhancing the lifespan of mechanical equipment, especially in high - humidity, dusty, or chemically exposed environments.

◊ Provide a protective and decorative finish for wooden furniture (chairs, tables, cabinets), floors, and wooden decorative items, aligning with the aesthetic and durability needs of residential and commercial spaces.

◊ Improve the durability of wood surfaces, protecting them from scratches during daily use, moisture absorption that causes warping, and UV damage that leads to discoloration.

Benefits

◊ Enhanced Durability for Core Applications: The excellent physical and mechanical properties of thermoplastic acrylic resins ensure that industrial coatings, automotive machinery coatings, and anti - corrosion coatings can withstand the rigors of heavy - duty use—from industrial equipment vibration to automotive road conditions. For wood coatings, this durability translates to resistance against daily wear, all reducing the need for frequent re - painting and maintenance.

◊ Long - Term Cost - Effectiveness Across Sectors: Due to their durability, coatings made with thermoplastic acrylic resins lower long - term costs: industrial facilities save on equipment downtime for re - coating, automotive manufacturers reduce warranty claims related to corrosion, wood product producers cut down on after - sales maintenance, and end - users enjoy longer - lasting surfaces.

◊ Aesthetic Consistency for Diverse Surfaces: The high gloss and color retention properties of these resins maintain a uniform, attractive finish—critical for automotive exteriors and industrial equipment that represents brand image, as well as for wooden furniture and floors that enhance living spaces. Unlike other resins, they resist fading and gloss loss even under prolonged UV exposure.

◊ Tailored Versatility for Specific Needs: Their compatibility with other resins allows formulators to create customized solutions—for example, harder formulations for industrial metal parts, more flexible ones for automotive body panels that absorb impact, and moisture - resistant blends for wood coatings. This versatility ensures they meet the unique requirements of each application area.

◊ Environmental Friendliness for Safer Workspaces: In optimized formulations, thermoplastic acrylic resins reduce volatile organic compound (VOC) emissions, making industrial coating workshops, automotive assembly plants, and woodworking facilities safer for workers. For wood coatings used in homes, lower VOCs also improve indoor air quality, aligning with modern environmental standards.

◊ Efficient Application to Boost Productivity: These resins can be easily processed and applied via spraying (ideal for large industrial equipment and automotive bodies), brushing (for small wooden items), or rolling (for wood floors and large machinery parts). This adaptability to common coating methods streamlines production lines, reducing application time and labor costs across industries.

◊ Reliable Corrosion Protection for Critical Components: For automotive machinery and anti - corrosion coatings, thermoplastic acrylic resins form a tight, chemical - resistant film that prevents rust and corrosion—extending the lifespan of automotive parts (such as engine blocks and chassis) and industrial machinery (like oil pipelines and chemical reactors) that are exposed to harsh substances.

◊ Consistent Performance in Variable Conditions: Their excellent weather resistance ensures stable performance in diverse climates—industrial coatings in hot, humid coastal areas resist moisture damage, automotive coatings in cold regions withstand freeze - thaw cycles without cracking, and wood coatings in sunny areas avoid UV - induced degradation, making them a reliable choice worldwide.

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :