This water-based acrylic colloidal emulsion is an environmentally compliant binder designed for formulating high-performance coatings. It offers excellent durability, UV resistance, and adhesion to various substrates while featuring low VOCs and superior colloidal stability for printing coating applications.

Item No :

Acrylic emulsionApplication :

PE Coating、Surface Printing Ink for Shopping Bags、PE CoatingSpecial Feature :

Improve printing adaptability, heat resistance, gloss, etcProduct Overview

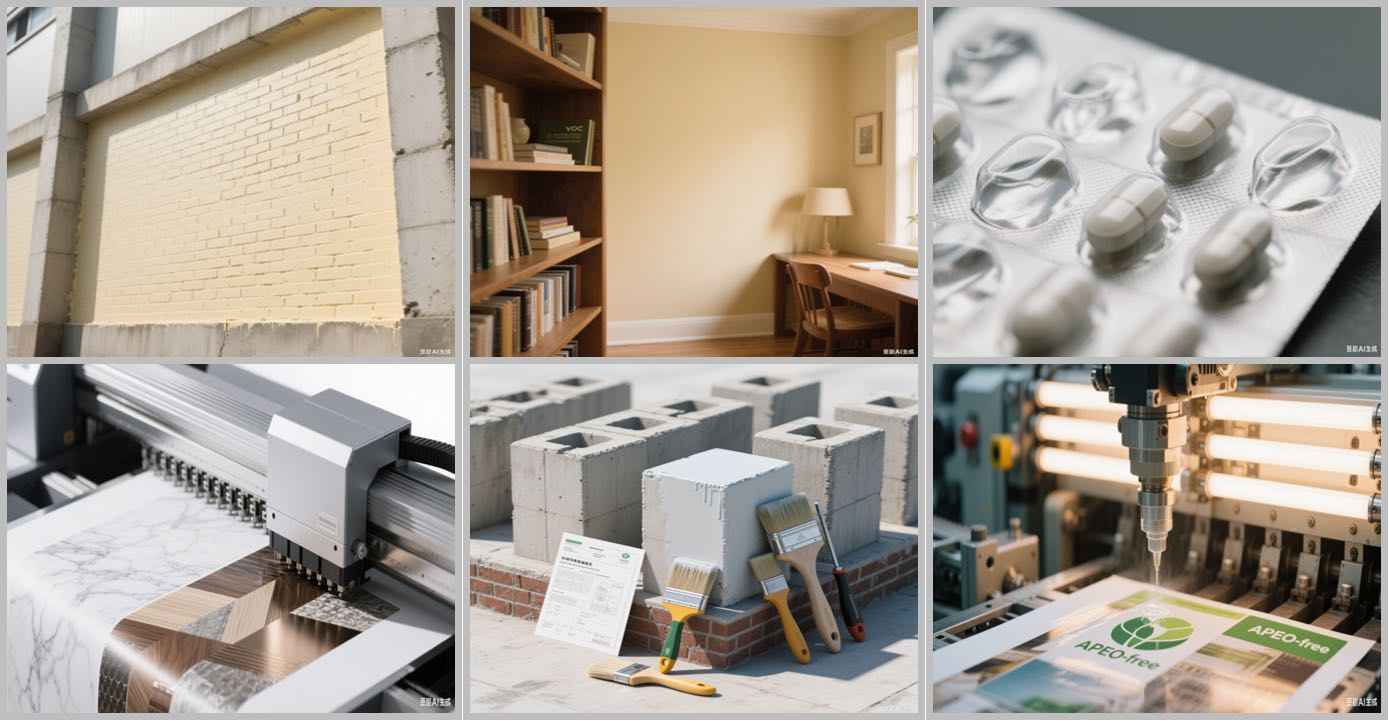

Runshine New Materials (Foshan) Co., Ltd. provides a range of high-performance Water-Based Acrylic Colloidal Emulsions engineered as primary binders for advanced coating formulations. These APEO-free emulsions are designed to deliver hard or soft films with tailored performance—the harder variants offer high durability and do not form film at room temperature, making them suitable for use with resins such as 7007 and 6027 to formulate economical UV ink primer varnishes and enhance flexographic ink properties including heat resistance and gloss. Softer, room-temperature film-forming types exhibit excellent adhesion to polyolefin films and are ideal for surface printing inks on shopping bags, as well as paper cup PE coatings where pH must be maintained below 8.3. All products support sustainability through low VOC content and compliance with international environmental regulations.

--------------占位---------------

Key Features

✧ Exceptional ecological compliance – This APEO-free, low-VOC (Volatile Organic Compound) emulsion meets stringent international regulations including REACH, EPA, and key eco-label standards.

✧ Superior hardness and blocking resistance – The hard, non-film-forming acrylic colloid at room temperature provides excellent hardness and anti-blocking properties for protective surface coatings.

✧ Enhanced adhesion on polyolefin substrates – Demonstrates strong adhesion on challenging surfaces such as untreated polyethylene (PE) and polypropylene (PP) films.

✧ Excellent formulation versatility – Acrylic emulsion could be combined with resins such as 7007 and 6027 to formulate economical yet high-performance primer varnishes for UV ink systems.

✧ Optimized for graphic arts and ink applications – Functions as a primary resin in flexographic inks to significantly improve print adaptability, heat resistance, gloss, and water resistance.

✧ Good pigment binding capacity – Water based acrylic emulsion exhibits efficient pigment wetting and dispersion stability, enabling high pigment loading for consistent coloration in ink and coating formulations.

✧ Thermally curing for high durability – Requires elevated temperatures for curing, resulting in a cross-linked film with robust resistance to abrasion and solvents.

✧ Broad compatibility with other dispersions – Shows good blendability with other water-based resins like polyurethane dispersions (PUDs) to tailor final film properties.

|

Parameter |

Typical Value |

Unit |

Notes |

|

Appearance |

Colorless and transparent |

– |

Visual inspection |

|

Solid Content |

43-47 |

% |

Can be adjusted for formulation |

|

Viscosity (25°C, Brookfield RV) |

<500CPS (25 ℃) |

mPa·s |

Spindle 3, 20 rpm |

|

Color |

<1 # (Fe-Co) |

/ |

/ |

|

Density (25°C) |

1.05–1.15 |

g/cm³ |

Typical value |

|

Recommended Solvents |

Water |

– |

For formulation compatibility |

|

Shelf Life |

12 |

months |

Stored in sealed containers at 5–35°C |

|

Storage |

Cool, dry place |

– |

Avoid direct sunlight and moisture |

| Acrylic emulsion | |||||||

| Model | Type |

Tg(℃) | mfft(℃) | Viscosity(mpa.s/25℃) |

Soild Content % |

pH Value | Character |

| RHERI®7090 | Acrylic emulsion |

90 | >80 | <500 | 46±1 | 7.0-9.0 | Hard, and does not form film at room temperature. Can be combined with 7007 and 6027 to formulate economical UV ink primer varnish. Also can be used as the main resin of flexographic ink to improve printing adaptability, heat resistance, gloss, etc. |

| RHERI®7007 | Acrylic emulsion |

8 | 7 | <500 | 46±1 | 7.0-9.0 | Soft, and can be film-formed at room temperature. Can be combined with 7090 and 6027 to prepare economical UV ink primer varnish. Can be used as the main resin of flexo ink to improve printing adaptability, water resistance, gloss, etc. Has good adhesion to polyolefin films and can be used as low-end Shopping bag surface printed with ink. |

| RHERI®6037 | Acrylic emulsion |

13 | <500 | 43±1 | 7.0-8.0 | Soft, and can be film-formed at room temperature. It is mainly used for PE coating of paper cups, recommended coating amount is GSM8-12. The pH value of the finished product should not be higher than 8.3 during use. | |

Applications

Our waterborne acrylic emulsion is engineered for high-performance, sustainable architectural and industrial coating systems that demand excellent durability, compatibility, and environmental compliance.

◊ Architectural exterior wall coatings – Provides weather resistance, hydrophobicity, and UV stability for durable facades

◊ Eco-friendly primer and topcoat systems for concrete and masonry – Enhances adhesion and barrier properties against moisture and alkalinity

◊ Low-VOC interior wall paints – Delivering scrub resistance and stain protection in living and working spaces

◊ UV-curable ink primer varnish for packaging prints – Combined with 7007/6027 for economical yet high-adhesion priming

◊ Flexographic printing inks – As main resin to improve printability, heat resistance, and gloss on films and papers

◊ Paper cup PE coatings – Offers good film formation at room temperature and water resistance at recommended coat weight (GSM 8–12)

◊ Surface printing ink for low-end polyolefin shopping bags – Ensures adhesion and print quality under economical formulation constraints

Note: For optimal performance in paper coating applications, maintain pH ≤ 8.3 during processing and application.

Benefits

Key Traits: APEO-free acrylic colloidal emulsion; exhibits excellent colloidal stability and compatibility with common coating additives; cures at ambient temperature to form a durable, transparent film.

Primary Benefits:

Delivers exceptional hardness and block resistance while maintaining substrate adaptability due to optimized colloidal particle design.

Provides excellent water and chemical resistance (including alcohols and weak alkalis) with minimal film formation temperature.

Ensures superior adhesion on diverse substrates (plastics, treated metals, paper, and polyolefin films) without additional primers.

Offers high gloss clarity and UV stability with low yellowing tendency, ideal for clear or pigmented coatings.

Enables rapid drying and enhanced printing adaptability in ink formulations, improving rub and scuff resistance.

Typical Uses:

Primer and topcoat formulations for paper/paperboard (e.g., paper cup PE coatings) requiring low coating weight (GSM 8-12).

Flexographic and gravure inks for packaging (e.g., shopping bag surface printing) with heat resistance and adhesion to polyolefins.

Economical UV ink primer varnishes when blended with resins (e.g., 7007, 7090, 6027) to balance cost and performance.

Industrial wood and metal coatings where hardness, water resistance, and low-VOC compliance are critical.

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :