Hydroxyl-functional Acrylic Resins play an essential role in the coatings industry, serving as key components in two-component polyurethane (2K PU) systems. These resins contribute hydroxyl (-OH) groups that react with isocyanate crosslinkers to form durable, high-performance coatings. Runshine produces a comprehensive portfolio of acrylic polyols, categorized by hydroxyl value, molecular weight, solid content, and solvent type—including conventional solvent-borne, high-solids, and waterborne dispersions. Products are engineered to offer a balance of reactivity, compatibility, flexibility, and resistance properties, making them suitable for a wide spectrum of coating applications.

Item No :

Hydroxyl-functional Acrylic PolyolApplication :

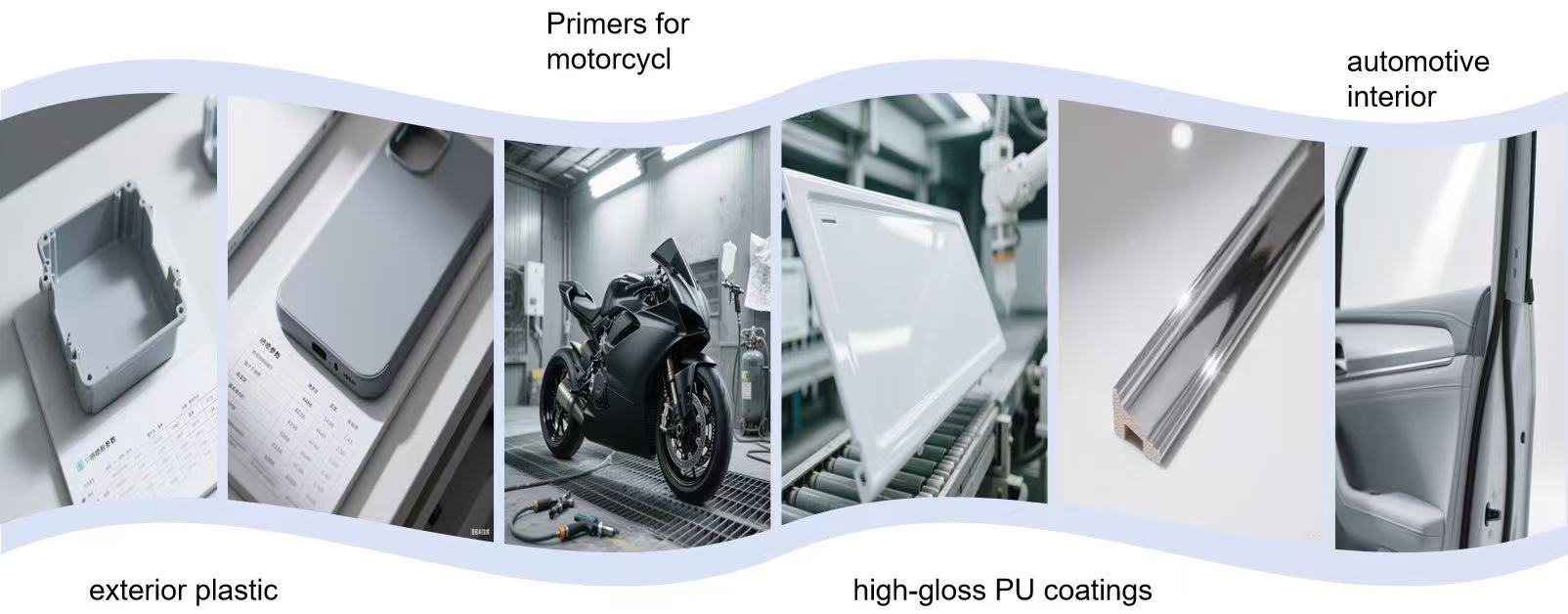

Primers for motorcycle and automotive interior / exterior plastic parts One-coat PU coatings on plastics One-coat PU coatings on plasticsSpecial Feature :

Excellent adhesion,salt-spray resistance, leveling,gloss and brasion resistance and compatibility,fullness,Cost-effective.Product Overview

Runshine New Materials (Foshan) Co., Ltd. is a specialized manufacturer of high-performance coating resins, including the HAC series of hydroxyl-functional acrylic resins (acrylic polyols). These products are designed for use in two-component polyurethane (2K PU) systems, offering excellent compatibility, reactivity with isocyanates, and outstanding durability.Our comprehensive portfolio encompasses various types of hydroxyl-functional acrylics, such as solvent-borne, water-dispersible, and high-solid versions, to meet diverse formulation needs. They are widely used in automotive, industrial, wood, and plastic coatings due to their strong resistance to yellowing, chemicals, and weathering.With a focus on quality and performance, Runshine provides reliable resin solutions that enhance coating hardness, flexibility, and finish quality for advanced applications worldwide.

--------------占位---------------

Key Features

✧Excellent reactivity with isocyanates – The hydroxyl-functional acrylic resin provides abundant OH groups for efficient cross-linking in two-component polyurethane coatings.

✧Superior weatherability and UV resistance – The acrylic polyol resin contributes to non-yellowing, durable films that retain gloss and color in long-term outdoor exposure.

✧Excellent compatibility with pigments and additives – The hydroxyl-functional resin ensures uniform dispersion and stability of aluminum flakes, matting agents, and colorants.

✧Good flow and leveling – The acrylic polyol enables smooth film formation with high distinctness of image (DOI) and reduced surface defects.

✧Strong adhesion to diverse substrates – The hydroxyl-functional acrylic resin adheres well to plastics, metals, and pre-treated surfaces without priming.

✧High mechanical resistance – The resin enhances hardness, abrasion resistance, and flexibility of the final coating film.

✧Broad formulation latitude – Hydroxyl-functional acrylic resins are available in a range of OH values and molecular weights to adjust crosslink density and performance.

✧Solvent-borne and water-borne variants – The acrylic polyol technology supports both conventional and low-VOC coating systems to meet environmental regulations.

|

Parameter |

Typical Value |

Unit |

Notes |

|

Appearance |

Transparent viscous liquid with little yellow |

– |

Visual inspection |

|

Solid Content |

50-90 |

% |

Can be adjusted for formulation |

|

Viscosity (25°C, Brookfield RV) |

1500-8000CPS (25 ℃) |

mPa·s |

Spindle 3, 20 rpm |

|

Color |

<1 # (Fe-Co) |

/ |

/ |

|

Density (25°C) |

1.05–1.15 |

g/cm³ |

Typical value |

|

Recommended Solvents |

Xylene, Butyl acetate,Dimethyl carbonate,Toluene,Butanol,Propylene Glycol Methyl Ether Acetate |

– |

For formulation compatibility |

|

Shelf Life |

12 |

months |

Stored in sealed containers at 5–35°C |

|

Storage |

Cool, dry place |

– |

Avoid direct sunlight and moisture |

| Hydroxyl-functional Acrylic Resins | ||||||||||||

| Product Name | Application Mode | Application Field | Key Technical Features | Solid Content (≥%) | Viscosity mPa·s/25°C | Acid Value mgKOH/g | Color | Hydroxyl Value | Hydroxyl Content (100% Resin) | Solvent | ||

|

Primer | Primers for motorcycle and automotive interior / exterior plastic parts | Excellent aluminum-flake orientation; broad compatibility; good substrate wetting | 50 | 2500 - 5500 | 2.0 - 6.0 | <1 | 60 | 0.018 | Butyl acetate | ||

|

Primer | Primers for motorcycle and automotive interior / exterior plastic parts | Superior leveling; broad compatibility; good substrate wetting | 60 | 4000 - 6000 | 3.0 - 7.0 | <1 | 60 | 0.018 | Xylene/Butanol | ||

| HAC8260 | Direct Coating | One-coat PU coatings on plastics | Excellent aluminum-flake orientation; high gloss; good wetting; cost-effective | 60 | 2000 - 4000 | 4.0 - 9.0 | <1 | 55 | 0.016 | Xylene/Butanol | ||

|

Direct Coating | One-coat PU coatings on plastics | Excellent aluminum-flake orientation; high abrasion resistance; good matting-particle orientation | 50 | 3000-7000 | 4.0-10.0 | <1 | 80 | 0.024 | Butyl Acetate/Propylene Glycol Methyl Ether Acetate | ||

|

Direct Coating | One-coat PU coatings on plastics | High gloss; excellent chemical resistance; outstanding salt-spray resistance | 60 | 3000 - 8000 | 3.0 - 8.0 | <1 | 95 | 0.0285 | Toluene/Dimethyl carbonate | ||

|

Direct Coating | One-coat high-gloss PU coatings on plastics | High gloss; excellent leveling and film fullness; strong adhesion to substrate | 90 | 1500 - 4500 | 2.0 - 8.0 | <1 | 90 | 0.027 | Butyl acetate/Dimethyl carbonate | ||

Applications

Our hydroxyl-functional acrylic resins are widely used in high-performance polyurethane coating systems, particularly for plastic substrates requiring excellent adhesion, flexibility, and aesthetics.

◊Primers for motorcycle and automotive interior/exterior plastic parts – delivering strong adhesion and superior topcoat compatibility

◊One-coat PU coatings on plastics – providing an optimal balance of appearance, chemical resistance, and mechanical protection

◊One-coat high-gloss PU coatings on plastics – ensuring exceptional DOI (distinctness of image), smoothness, and durable finish without basecoat

Benefits

1. Hydroxyl-functional Acrylic Resins for Plastic Parts Primers

Key Traits: High hydroxyl value; excellent adhesion to various plastics; good substrate wetting

✧Primary Benefits:

Enables excellent aluminum-flake orientation and uniform metallic effect

Provides broad compatibility with polyisocyanates and other coating components

Ensures superior leveling and film integrity on plastic substrates

✧Typical Uses:

Primers for motorcycle and automotive interior/exterior plastic parts: Deliver strong adhesion and a smooth base for topcoats, ensuring durability and aesthetic quality.

2. Hydroxyl-functional Acrylic Resins for One-Coat PU Systems

Key Traits: Balanced OH functionality; high gloss retention; good pigment wetting and dispersion

✧Primary Benefits:

Delivers high gloss and excellent aluminum-flake orientation in a single layer

Offers cost-effectiveness while maintaining high abrasion and chemical resistance

Ensures effective matting-particle orientation for consistent finish

✧Typical Uses:

One-coat PU coatings on plastics: Supplied as an all-in-one solution with high durability, chemical resistance, and outstanding salt-spray protection.

3. Hydroxyl-functional Acrylic Resins for High-Gloss Plastic Coatings

Key Traits: High reactivity; excellent flow and leveling; strong intercoat adhesion

✧Primary Benefits:

Achieves high gloss and exceptional film fullness without multiple layers

Enhances coating durability and visual distinctness of image (DOI)

Provides strong adhesion to plastic substrates, eliminating the need for primers

✧Typical Uses:

One-coat high-gloss PU coatings on plastics: Used in consumer electronics, automotive trims, and household appliances where aesthetics and resistance are critical.

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :