Water-based polyurethane resin (WPU) has emerged as a transformative material in leather finishing, revolutionizing traditional solvent-based systems with its eco-friendly profile and advanced functional properties. Below is a detailed exploration of its applications, characteristics, and competitive advantages in this domain

Item No :

RHERI®L2027Application :

Suitable For Wood coatings, industrial paints, leather finishes, and package printing, textile printing etcSpecial Feature :

Solvent-free, aliphatic, Excellent adhesion on nature leather or artificial leather with gloss and matte,anti-abrashonProduct Description

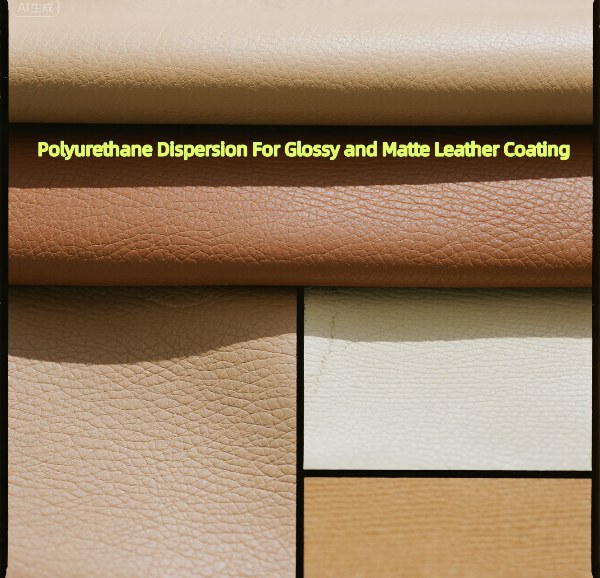

RHERI®L2027 is a water-based aliphatic polyurethane dispersion with glossy and matte application for various soft-feeling coating ,especially for leather surface finishing and coating .Water-borne polyurethane is rapidly becoming the dominant polyurethane binder in modern leather finishing lines. Compared with traditional solvent systems, a water based polyurethane dispersion—often simply called a polyurethane emulsion—offers tanners a polyurethane resin that is almost odor-free, non-flammable and extremely low in VOC. In practice, a cationic polyurethane dispersion is preferred because the anionic character of most leathers gives the polyurethane binder outstanding anchorage; the same polyurethane resin formulation can later be over-sprayed with an anionic polyurethane emulsion top-coat without risk of delamination.

Technical Data

| Apprearance | Milky white |

| Solid Content(%) | 35±1 |

| pH(25C°) | 7.0 - 9.0 |

| Viscosity(25C°,Mpa.s) | <1000 |

| Modulus(Mpa) | 1-30 |

| Elongation% | 800-1600 |

| Tensile Srtrength(Mpa) | 15-40 |

Main Feature

1.Environmental and safety profile • water based polyurethane binder is supplied as a polyurethane dispersion in water, so the formulation contains little or no organic solvent. This makes the polyurethane emulsion non-flammable and almost odor-free, cutting VOC emissions to well below 50 g L⁻¹ in most cases. • Operators no longer need explosion-proof spray booths or solvent recovery plants, so the polyurethane resin helps tanners meet REACH, ZDHC and brand-restricted-substance lists with minimal investment. 2.Film performance and “hand” • The same polyurethane binder can be engineered with soft and hard segments, allowing the resulting polyurethane resin film to be both flexible and highly abrasion-resistant. • After drying, the polyurethane emulsion forms a microporous yet continuous coating; the leather retains its natural breathability while gaining water- and stain-repellency. • Cross-linkable grades—where a polycarbodiimide is post-added to the polyurethane dispersion—deliver wet-rub resistance above 500 cycles (DIN EN ISO 11640) without stiffening the grain. 3.Process flexibility • Because the polyurethane emulsion is already dispersed, it can be diluted with de-ionised water and sprayed, roll-coated or curtain-coated without additional reducers. • A cationic polyurethane dispersion makes an excellent first “tie-coat,” anchoring strongly to the anionic leather surface; an anionic polyurethane binder can then be applied as a top-coat without delamination. • Clean-up requires only warm water and soap, so downtime between color changes is minimal. 4.Cost-in-use and versatility • The same polyurethane resin family is available in high-solids (40–50 %) or ready-to-use low-viscosity grades, letting the tanner optimize mileage and line speed. • Matte or gloss, full grain or corrected grain, automotive or fashion—one water based polyurethane binder platform can be tuned by solids, particle size and cross-link density to fit every article. 5.Regulatory and brand compliance • Major chemical suppliers now offer polyurethane dispersion grades certified to OEKO-TEX, GOTS and LWG protocols, ensuring that the polyurethane emulsion itself, as well as the finished leather, passes stringent brand audits.

Application

Water based Polyurethane Binder is suitable For Wood coatings, industrial paints, leather finishes, and package printing,textile printing etc.Excellent bonding & wetting on PET & OPP films for printing ink

Storage&Remarks

Waterborne Polyurethane resin is stable when stored at 20°C for 6 months after delivery date. The recommended temperature range is 5~30 oC. Freezing or storage at higher temperature than 30°C, can affect the viscosity or the average particle size and finally lead to a sedimentation or coagulation. A contamination with bacteria, fungi or algae can damage the product irreversible

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :