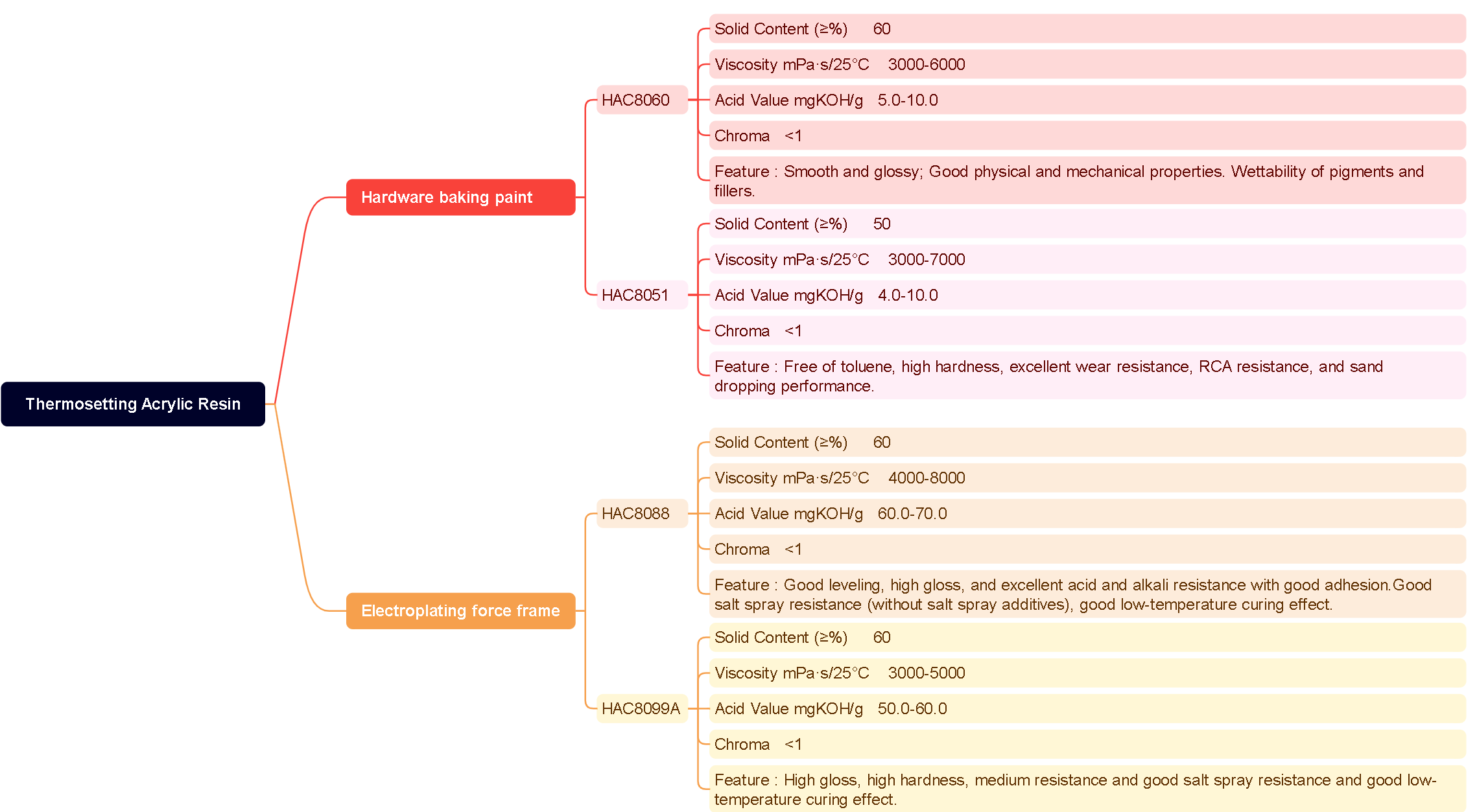

Our thermal-setting acrylic resin products are designed to meet the high demands of industrial coating applications, especially in the fields of automotive machinery and anti-corrosion coatings. These resins play a crucial role in formulating high-performance industrial paints.

Item No :

Thermal-setting acrylic resinApplication :

Industrial, automotive machinery & anti-corrosion coating.Special Feature :

High hardness, adhesion & resistance, fits multiple scenarios.Product Overview

The thermal-setting acrylic resins are composed of carefully selected acrylic monomers, synthesized through precise polymerization processes to ensure consistent quality and performance. To tailor the resins for specific coating requirements in industrial coatings,automotive machinery, and anti-corrosion coatings applications, they are often blended with compatible solvents, specialized catalysts, and functional additives—these components work in synergy to enhance properties like curing efficiency, flowability, and storage stability. A key characteristic of these resins is their cross-linkable molecular structure: the presence of reactive functional groups (such as hydroxyl, carboxyl, or epoxy groups) enables the formation of a dense three-dimensional network during the thermal curing process. This cross-linked structure is fundamental to elevating the performance of coatings formulated with the resin, as it directly contributes to attributes like hardness, chemical resistance, and adhesion—all critical for meeting the rigorous demands of industrial, automotive machinery, and anti-corrosion coating scenarios.

--------------占位---------------

Key Features

◊ High Hardness: Provide coatings with excellent hardness, ensuring good scratch and abrasion resistance. This is crucial for industrial applications (such as heavy-duty industrial equipment) where the coated surfaces are likely to be subjected to mechanical stress, and for automotive machinery parts that come into contact with other components during operation.

| Parameter | Typical Value | Unit | Notes |

| Viscosity (25°C, Brookfield RV) | 50-60 | mPa·s | Spindle 3, 20 rpm |

| Acid Value | 4.0-70.0 | mgKOH/g | / |

| Chroma | <1 | – | / |

| Shelf Life | 12 | months | Stored in sealed containers at 5–35°C |

| Storage | Cool, dry place | – | Avoid direct sunlight and moisture |

Applications

◊ Industrial Coatings: Widely used in formulating industrial paints for general industrial equipment (such as pumps, valves, and conveyor systems). These paints, enhanced by thermal-setting acrylic resin, offer reliable protection against mechanical wear and environmental factors, while also providing decorative value that enhances the professional appearance of industrial products.

Benefits

◊Enhanced Durability: The cross-linked structure formed by the thermal-setting acrylic resin significantly improves the durability of coatings used in industrial coatings, automotive machinery, and anti-corrosion coatings applications. This durability allows coatings to withstand harsh conditions—including mechanical impact, chemical spills, and extreme temperature fluctuations—for extended periods, reducing the need for frequent recoating and lowering maintenance costs.

◊Improved Performance Consistency: Coatings formulated with these resins deliver consistent performance across different batches and application scenarios. For automotive machinery manufacturers, this means uniform protection for every part; for industrial facilities, it ensures that equipment coatings maintain their function even in varying operational conditions, minimizing unexpected downtime.

◊Strong Substrate Compatibility: The superior adhesion of thermal-setting acrylic resin ensures compatibility with a wide range of substrates commonly used in industrial and automotive applications (such as steel, aluminum, and galvanized metals). This eliminates the need for additional primers in many cases, simplifying the coating process and reducing material costs.

◊Aesthetic Versatility: Beyond protection, these resins enable coatings to achieve a range of aesthetic effects—from high-gloss finishes for automotive body panels to matte or textured finishes for industrial equipment. This versatility allows manufacturers to meet both functional and design requirements, whether creating a sleek look for automotive machinery or a low-reflectivity surface for industrial tools.

◊Efficient Curing Process: Thermal-setting acrylic resins cure efficiently under standard industrial heating conditions, reducing curing time compared to some alternative resin types. For manufacturers of industrial equipment and automotive parts, this shorter curing cycle speeds up production workflows, increasing overall operational efficiency and output.

◊Long-Term Cost Savings: While the initial cost of thermal-setting acrylic resin may be higher than some conventional resins, the long-term savings are substantial. The extended service life of coatings, reduced maintenance needs, and simplified application process all contribute to lower total cost of ownership—especially for industries relying on durable industrial coatings, automotive machinery coatings, and anti-corrosion solutions.

◊Environmental Resilience: The chemical and weather resistance of these resins ensures that coatings remain effective even in challenging environments, such as coastal areas (for marine anti-corrosion coatings) or industrial zones with high pollution levels. This resilience protects valuable assets (like automotive machinery and industrial infrastructure) from premature degradation, preserving their value over time.

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :