Polyisocyanate hardener stands as a cornerstone in high-performance coating formulations, offering a wide array of options tailored to diverse application needs. Runshine New Materials (Foshan) Co., Ltd. specializes in producing various polyisocyanate hardeners, ranging from solvent-based to waterborne types, and including both blocked and unblocked variants. These hardeners, also known as crosslinkers, derive from different isocyanate monomers such as HDI, IPDI, TDI, and MDI, each bringing unique properties to meet specific coating requirements. What makes polyisocyanate hardener indispensable is its unique reactivity with polyols or other active hydrogen groups, which enables the formation of robust, crosslinked polymer networks—networks that underpin the durability and performance of the final coatings.

Item No :

Polyisocyanate hardenerApplication :

Polyisocyanate hardener serves diverse coatings like automotive and marine.Special Feature :

Polyisocyanate hardener offers weatherability, fast cure and good adhesion.Product Overview

Polyisocyanate hardener typically appears as a transparent viscous liquid with a slight yellow tint, as observed through visual inspection. Its solid content ranges from 60% to 100%, a parameter that can be adjusted to fit different formulation needs. When measured at 25°C using a Brookfield RV viscometer with spindle 3 at 20 rpm, its viscosity falls between 10000 and 120000 mPa·s. The color of the polyisocyanate hardener is rated below 1# on the Fe-Co scale, ensuring it does not compromise the aesthetic of the coatings it is mixed with. With a density of 1.05–1.15 g/cm³ at 25°C, it exhibits consistent physical properties that facilitate easy integration into various coating systems. Recommended solvents for this polyisocyanate hardener include xylene, ethyl acetate, PM, PMA, IPA, and MEK, all chosen for their compatibility with the formulation. When stored in sealed containers at 5–35°C in a cool, dry place, away from direct sunlight and moisture, it maintains its quality for up to 12 months.

--------------占位---------------

Key Features

✧Exceptional weatherability: Aliphatic isocyanate crosslinker systems in polyisocyanate hardener deliver UV-stable coatings, ensuring long-term durability in outdoor environments such as marine vessels and architectural exteriors.

✧Rapid cure speed: Polyisocyanate hardener enables fast development of handling strength at room or slightly elevated temperatures, increasing production throughput and reducing manufacturing downtime.

✧Adjustable reactivity: Formulators can fine-tune pot life and gel time by selecting different functionalities or blocked variants of polyisocyanate hardener, allowing customization for specific application needs.

✧Excellent adhesion: Polyisocyanate hardener forms strong bonds with metals, plastics, glass, and composites without additional primers, simplifying the coating process and ensuring long-term adherence.

✧Low-temperature flexibility: Polyisocyanate hardener retains elastomeric properties at sub-zero temperatures, making it suitable for automotive and aerospace seals with temperature fluctuations.

|

Parameter |

Typical Value |

Unit |

Notes |

|

Appearance |

Transparent viscous liquid with little yellow |

– |

Visual inspection |

|

Solid Content |

60–100 |

% |

Can be adjusted for formulation |

|

Viscosity (25°C, Brookfield RV) |

10000~120000CPS (25 ℃) |

mPa·s |

Spindle 3, 20 rpm |

|

Color |

<1 # (Fe-Co) |

/ |

/ |

|

Density (25°C) |

1.05–1.15 |

g/cm³ |

Typical value |

|

Recommended Solvents |

Xylene, Ethyl Acetate, PM,PMA,IPA,MEK etc |

– |

For formulation compatibility |

|

Shelf Life |

12 |

months |

Stored in sealed containers at 5–35°C |

|

Storage |

Cool, dry place |

– |

Avoid direct sunlight and moisture |

| Blocked polyisocyanate Hardener | ||||||

| Product Name | Isocyanate | Type | Solvent | Solid Content% | Visc. | Properties Application |

| RHEBL3075 | HDI | Blocked polyisocyanate |

Solvesso 100 |

75 | 1500- 5500 |

Weather-stable,non-yellowing baking systems for industrial finishing,coil and tone-chip primer surfacers;also as an additive to improve adhesion and elasticity |

| RHEBL3080 | TDI | Blocked polyisocyanate |

Mixed solvent |

80 | 3500- 8500 |

Baking systems for industrial finishing,coil and tone-chip primer surfacers;also as an additive to improve adhesion and elasticity |

| RHERI®C30 | HDI | Blocked polyisocyanate |

Water | 30 | <600 | C30 is a curing agent that is very suitable for printing and coating. The activation period is more than one week. The storage temperature of the remaining ink is not recommended to exceed 40°C. The higher the temperature, the more beneficial to the cross-linking reaction. After flash-drying, curing at 60-80°C for 48 hours has significant effect on improving the resistance. |

| For hardener list in detail ,kindly contact me for more | ||||||

Applications

✧Premium PU coatings for wood and metal: Polyisocyanate hardener enhances scratch resistance and imparts smooth glossy or matte finishes, elevating the aesthetic of furniture, cabinetry, and metal fixtures.

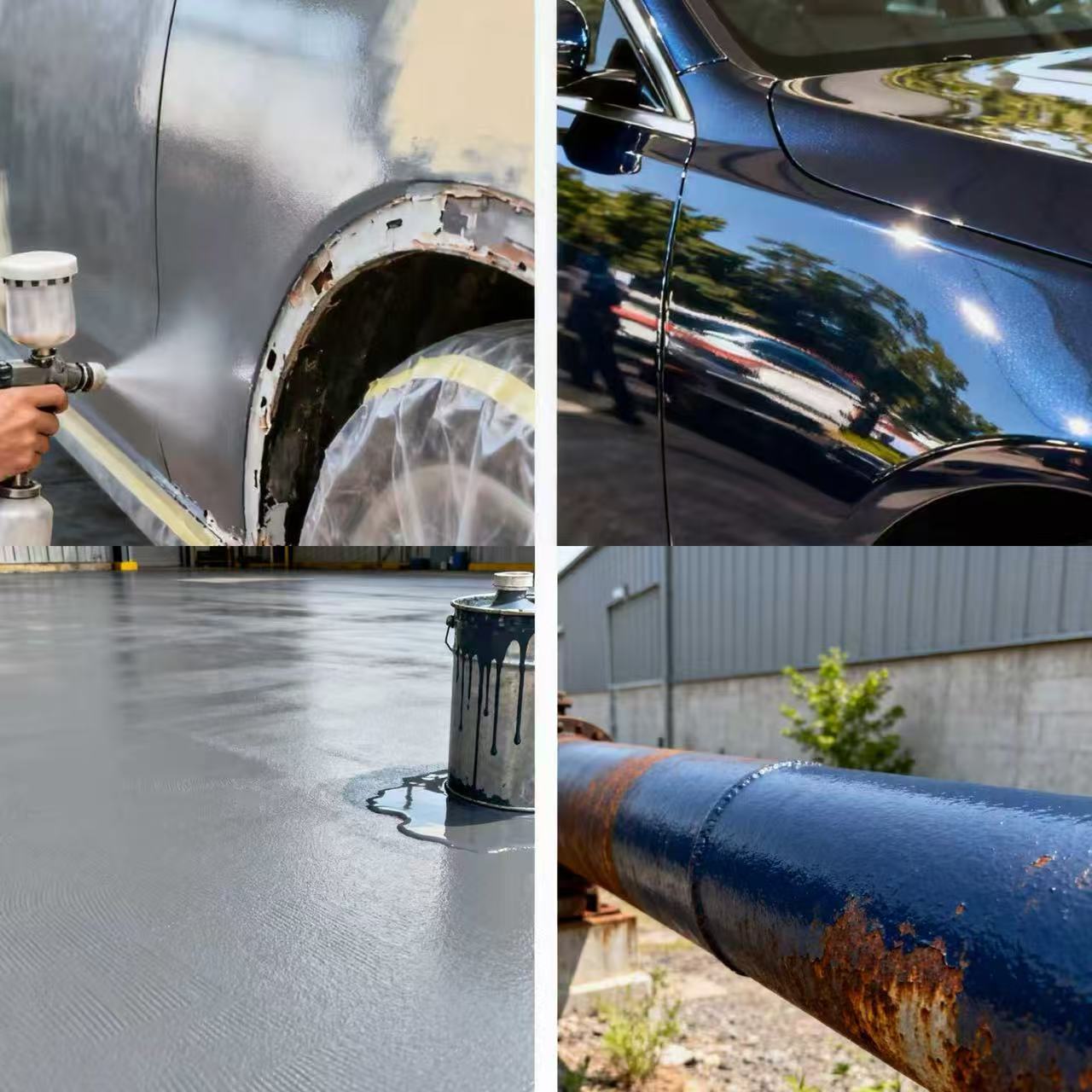

✧Automotive coatings: Unblocked polyisocyanate hardener enables quick repairs in refinish coatings with minimal downtime; solvent-based variants in OEM topcoats deliver high-gloss, durable finishes resistant to wear and UV damage.

✧Industrial coatings: Polyisocyanate hardener is used in floor coatings to withstand chemical exposure and heavy loads, and in corrosion-resistant coatings for outdoor metals to protect against rust and degradation.

✧Textile coatings and printing inks: Waterborne polyisocyanate hardener variants contribute to low-VOC formulations with excellent adhesion and flexibility, meeting industry performance needs.

✧Marine coatings: Polyisocyanate hardener resists saltwater and UV damage, ensuring the longevity of ships and offshore structures in harsh marine environments.

Benefits

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :