Polycarbonate Polyurethane Dispersions (PUDs) are water-based alternatives to solvent-based polyurethanes. Unlike solvent-based resins, PUDs rely on water evaporation for film formation. Their polymer backbone composition and formulation additives significantly affect properties like adhesion, flexibility, and durability. Proper formulation is crucial to optimize performance, as PUDs require balancing hydrophilic and hydrophobic components for effective film formation and mechanical properties.

Item No :

Water Based Polyurethane Dispersion PUDApplication :

Suitable for various coating and inkSpecial Feature :

Solvent-free, aliphatic, Excellent adhesion gloss and matte,anti-abrashon,waterproofProduct Description

Water-based Polyurethane dispersions (PUDs) are a rapidly growing segment of the polyurethane coating industry due to environmental legislations such as the clean air act and also due to technological advances, that has made them an effective substitute for the solvent-based analogs. They are versatile and environmentally friendly coating materials that are available in a wide range of hardness and solid content. Their zero to low volatile organic content facilitate their formulation into a compliant coating for many different substrates. Their versatility and wide range of superior properties, such as abrasion resistance, impact strength and low temperature flexibility are the driving forces to their continuously expanding usage in many applications.

The PUDs are not a direct plug-in for the solvent-based polyurethanes. The film forming mechanism of the PUDs is very different from that of the solvent-based resins. In order to realize their optimum properties, they have to be skillfully formulated. The composition of the polymer backbone as well as the formulating ingredients will have significant influence on film formation properties.

Polyurerthane dispersions are fully reacted polyurethane/ polyureas of small and discrete polymer particles ranging in sixe from 0.01-5.0 microns in a continuous water phase. They are free of isocyanate residues and have a zero or a very low volatile organic content (VOC). They are safe to handle and are a good choice for compliant coatings. PUDs can be made to have 30-65% solid content and a wide range of film hardness.

One of the drawbacks of PUDs is their relatively higher cost. To compensate for the higher cost and in some cases, to improve adhesion to certain substrates, the PUDs are blended with other low cost dispersions. Acrylic emulsions are the most commonly used blending materials due to the familiarity of the formulators with their properties.

Solvent-based coatings are being replaced with eco-friendly water-based polyurethane dispersions.

Stringent production standards required in the food, pharmaceutical and personal hygiene industry, the world over, dictate that the actual formulating area must be sterile and clean from bacteria and pathogens. These rooms are generally airconditioned, sealed environments, under pressure of two isobars. Inside, the floors, walls and ceilings are coated with a tough resilient seamless coating to prevent biological contamination such as germs or viral infestation which would find a hold in the cracks or joints in the tiles or canters.

Epoxy coating and solvent-based polyurethane coatings which are used in developing countries such as India for cleanrooms, are highly toxic in nature and therefore fraught with health hazards. The solvent added to the above coatings for better finish and to bring down the cost of these coatings, is the proverbial nail in the coffin due to its negative long-term effects on human health.

In the developed world, especially Europe and the Americas, the use of solventbased coatings are being phased out. These are being replaced with waterbased Polyurethane dispersions (PUDs). PUDs are waterborne systems, ecofriendly, having all the properties of the solvent-based systems, minus the hazards. PUDs can be formulated to not only make floor coatings but also for the walls which arte tough and resilient with scratch resistance and stability.

The PUDs have a life of 10 years even in exposed areas as they have excellent UV resistance against yellowing, cracking or peeling. They enjoy enhanced penetration into the substrate and offer better bonding viz a viz water based acrylics. They can also be formulated into coatings for glass, clear glossy finishes for wood and veneers, anti-corrosive coatings for metals, even in exposed areas with an enhanced life span. Technology is moving rapidly as also awareness levels, with the advanced countries already having phased out solvent-based systems in their work places and living environments for health reasons.

Cleanrooms in Indian pharmaceutical companies are not all designed with waterbased PUDs. Epoxy and solvent-based coatings are still used in cleanrooms. Hardeners used in solvent-based polyurethane coatings contain MDI, the health hazards of which can result in skin rashes, cornea damage, asthma like reactions, allergies. Isocyanates are also known to cause tumours in rats and are therefore classified as human carcinogens.

Solvents are also used in many items like Paints, varnishes, lacquers, paint removers, etc. They include commonly used chemicals such as alcohol, mineral spirits, petroleum distillates, turpentine, benzene, perchloroethylene, toluene, xylene, trichloroethylene, gasoline, kerosene, butyl acetate, acetone, metyl ethyl ketone (MEK), methyl isobutyl ketone (MIBK). The list goes on.

As per OSHA (Occupational Safety and Health Administration, US Department of Labour), health hazards associated with solvent exposure include cancer, skin infections and reproductive damage. The smell of solvents hangs in the air, days and weeks after the application of Epoxy solvent-based polyurethane coatings.

Solvent-based coatings are being phased out and replaced with water-based PUDs, that are eco-friendly with all the good properties of the solvent-based systems, but, minus the hazards.

Technical Data

| Apprearance | Milky white |

| Solid Content(%) | 30-60% |

| pH(25C°) | 7.5 - 9.5 |

| Viscosity(25C°,Mpa.s) | <1000 |

| Modulus(Mpa) | 1-30 |

| Elongation% | 200-1600 |

| Tensile Srtrength(Mpa) | 10-45 |

Main Feature

The first step in the preparation of aqueous polyurethane dispersions (PUD) is the formation of a medium molecular weight, isocyanate terminated prepolymer. This prepolymer is synthesised from the reaction between a di- or polyol with a stoichiometric excess of di- or polyisocyanate (see Fig 1) under anhydrous conditions.

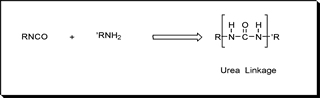

Water-solubilising groups are introduced in various ways, either into the prepolymer prior to chain extension or as part of the chain extension agent. The prepolymer is chain extended to increase molecular weight by reaction with a dior polyamine at the aqueous dispersion step.

(see Fig 2).

The resulting product is a high molecular weight aqueous dispersion of thermoplastic polymer that contains no unreacted isocyanate groups. This prepolymer mixing process is extremely flexible in terms of the range of aqueous dispersions that can be produced.

PUD's can be usefully described using three broad definitions:

1. The solubilisation mechanism

· Anionic - These products have monomers containing carboxylic acid or sulphonic acid groups incorporated into the prepolymer. The solubilising group must have low reactivity towards isocyantes. The acid groups are neutralised by reaction with a base before or during the dispersion stage. The pH of formulations must usually be kept in the range 7-10.

· Cationic - These products are prepared by incorporating a tertiary amine group into the prepolymer, which is ionised by the reaction with a strong acid. Formulations must usually be kept below a pH of 7.

· Non-nionic - These products have hydrophilic moieties within the prepolymer backbone as the solubilising mechanism. These grades are normally tolerant to wide pH changes. They have less water resistance properties in a finished application due to the retention of the hydrophilic nature of the polymer.

2. The type of polyisocyanate

· Aromatic - These less expensive products confer toughness but have poor light stability. Exposure to UV light will cause yellowing.

· Aliphatic - More expensive aliphatic products impart better hydrolytic stability and have improved UV light degradation. They are non-yellowing.

3. The type of polyol

· Polyether - Lower cost polyether polyols result in products having good hydrolysis resistance, softness and flexibility.

· Polyester - Large variations of polyester polyols are available to confer a wide range of properties. They generally give good weathering properties, good abrasion resistance, toughness and chemical resistance. They also have good adhesion to low surface energy substrates.

· Polycarbonate - These more expensive products confer similar properties as polyesters but they have better hydrolytic stability, stain resistance and toughness.

Our latest developments have been in the field of Water based Polyurethane Dispersions (PUD’s). Polyurethane dispersions (PUDs) are extensively used mainly because of their excellent chemical, solvent, abrasion, scratch resistance, flexibility & adhesion. Increased emphasis towards the use of nonpolluting coating has led to the development of water borne polyurethane system. Water-based polyurethanes are becoming more and more important as binders in applications involving construction chemistry.

Application

Polyurethane dispersions are used as the main or auxiliary binders in "Hygiene" coatings, where the coatings main requirements of toughness and reasonable gloss, single-pack, water based and low odour, easy cleanability, rapid drying and fast property developments are some of the more important properties.

Food, pharmaceutical and personal hygiene plants, hospitals and nursing homes, hotels and restaurants and anywhere there exists a requirement for clean, bacteria resistant surface, these coatings provide the answer. "Hygiene Coatings" may be used on walls, ceilings and floors, all based on specific types of polyurethane dispersions.

"Thermal Reflective - Insulating Coatings", is another entrant in the construction exterior coatings market. These functional polyurethane coatings are specially formulated to reflect, refract and dissipate the radiant heat of the Sun. Use of these polyurethane coatings on exterior of Roofs, Building Side Walls, Liquid and Gas Storage Tanks, Boilers, Air Condition Ducts, and many more areas keeps the interiors cool, thus saving evaporation losses and reducing energy requirements. The "Thermal Reflective - Insulating Coatings" can, additionally be provided with waterproofing properties, especially when used on building roofs.

Sealers for Concrete Waterborne polyurethane dispersion based Concrete Sealers can be designed to penetrate deeply into the pores of masonry surfaces to "Seal" the concrete, from ingress of sulphates & chlorides and thereby provide corrosion protection to the steel reinforcements. Floor Sealers can also be formulated to stop the concrete floors from dusting and to form a foundation to support different types of polyurethane based coatings. The sealants may be formulated to provide excellent chalk binding & alkali resistance properties. These concrete sealers are unpigmented, resin-rich compositions, but may also be pigmented to fill concrete sblocks in one coat.

If the floor is dusty or if the floor in a supply room, warehouse, restaurant, shopping area and requires to be made resistant to pedestrian traffic, or if the look and aesthetics of a floor has to be improved upon, a single-component water-based polyurethane floor coating system should be suitable. These coatings, in addition to being water-based have low VOC and practically no odour. They dry quickly and can be recoated within 2 to 4 hours depending on the prevailing ambient temperature and humidity and are ready to take traffic within 24 hours or earlier.

The water-based polyurethane coatings can be applied directly to cleaned concrete floors as also on previously painted surfaces provided the existing paints are still in good condition. Porous floors however need a penetrative & impregnating sealant as the first coat. Maximum dry film thickness recommended for such floors is 60 microns. They are one-component coatings hence there is no on-site mixing required nor is a limit on their pot life placed and they can be applied quickly and easily by brush and roller.

The coated floors become less susceptible to pick up dirt, and are fast and easy to clean. These coatings possess adequate wear and chemical resistance for the purpose they are designed for.

While many colours can be formulated using the water-based polyurethane dispersions, only a limited range of colours provides the decorative effect for commercial floors. The decorative effect can be further enhanced using multicoloured pigment flakes, quartz sand, powdered hard minerals, etc. Using an appropriate primer, these coatings can also be painted over linoleum, vinyl tiles and sheets, over decorative cement tiles, slabs, etc.

In the case of floors that are subject to significant wear and tear due to heavy vehicular traffic, protection and ongoing maintenance is essential. Floor coatings that would stand up over a long period of time to heavy traffic loads, such as forklifts and vehicles that carry heavy trailers and large parts and in addition have high abrasion resistance can be formulated using waterborne polyurethane dispersions crosslinked with polyisocyanates. These coatings dry rapidly and can be walked on in less than 3 to 4 hours after application and they are odour-free.

The coating system includes a water-based epoxy primer or 100% solids epoxy primer, a 100% solids epoxy intermediate coat and a pigmented two-component water-based polyurethane topcoat. The primer provides good adhesion and moisture resistance and is applied at 1.2 to 1.5 mils dry. The intermediate coat may be applied between 5 and 10 mils dry depending on the load behaviour required of the floor. The polyurethane topcoats offer excellent gloss retention, long-term colour retention and high wear resistance when applied at 1.9 to 2.4 mils dry film thicknesses.

The need to protect concrete surfaces from early deterioration has been an issue that has been debated for many years. With the rapid industrialization that is taking place in the country, pollution is likely to be one of the causes for shortening the life of concrete structures. Unless protected, the replacement cost of these structures can become phenomenal. Water-based PUDs, can be tailored to suit every single application. They can be made rigid and hard and they can be designed to be flexible and soft, and anything in between. PUDs are resistant to UV light and are known to retain gloss levels for long periods. They are compatible with many acrylic and other dispersed resins, and can be easily pigmented. PUDs are available as thermoplastic and thermoset resins and can be readily cross-linked with a variety of commercially available cross-linkers to further enhance their properties and in designing high-quality and durable coatings.

Storage&Remarks

Waterborne Polyurethane Binder is stable when stored at 20°C for 6 months after delivery date. The recommended temperature range is 5~30 oC. Freezing or storage at higher temperature than 30°C, can affect the viscosity or the average particle size and finally lead to a sedimentation or coagulation. A contamination with bacteria, fungi or algae can damage the product irreversible

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :