Our thermally activated, moisture-curing PUR adhesives are high-performance thermoset systems designed for automated flat lamination. They offer a wide application temperature range (110°C - 140°C) and customizable open times to ensure superior bonding, exceptional aging resistance, and high production yields on diverse substrates including MDF, metals, plastics, and engineered panels for demanding furniture and architectural applications.

Item No :

PUR AdhesivesApplication :

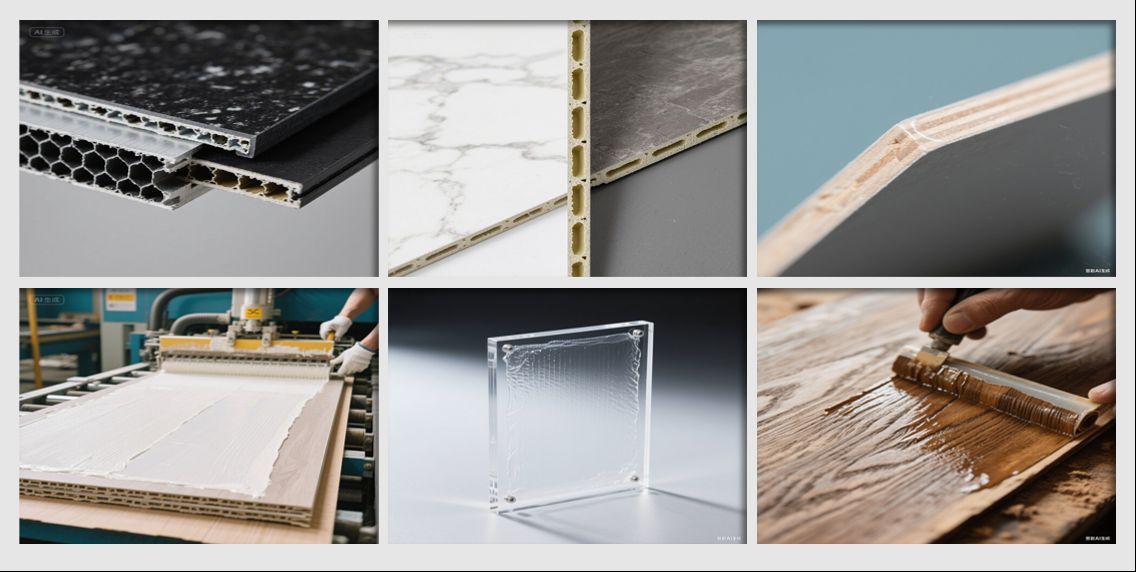

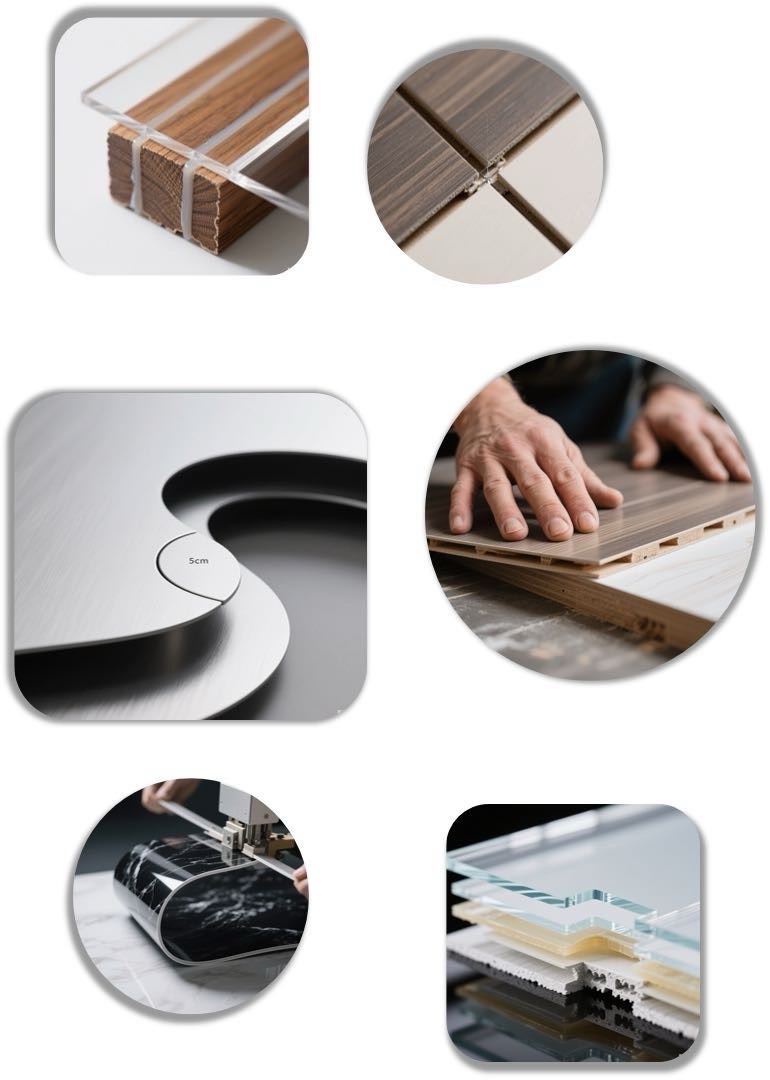

MDF, Decorative Panels, Acrylic Sheets, Aluminum Panels, SPC Panels, Carbon Crystal Panels, Wood Veneers, PET Lamination, etc.Special Feature :

Excellent application range, high and low-temperature performance, superior aging resistance, high yield, and exceptional PET compatibility.Product Overview

Runshine New Materials (Foshan) Co., Ltd. offers a series of high-performance, thermally activated, moisture-curing polyurethane (PUR) hot melt adhesives engineered for high-speed flat lamination processes across diverse climatic conditions. These reactive thermoset systems provide strong, durable bonds to a wide variety of substrates including MDF, wood veneers, metals, plastics (PET, acrylic), SPC, and carbon crystal panels. Formulated with specific ambient temperature tolerances (0°C to 43°C) and controlled open times (4-30 minutes), they ensure excellent processing adaptability, high production yield, and reliable performance. Key characteristics such as excellent aging resistance, thermal stability, and tailored reactivity—including specialized efficacy for PET films—make them ideal for demanding furniture, interior decoration, and architectural applications. All products are designed for application at 110°C - 140°C and support sustainable manufacturing with low VOC emissions.

--------------占位---------------

Key Features

✧ Moisture-curing polyurethane (PUR) chemistry – Provides superior bond strength and durability through a reactive curing mechanism that forms cross-linked networks resistant to heat, aging, and solvents.

✧ Controlled open time versatility – Available in formulations with open times ranging from 4 to 30 minutes at 25°C to accommodate various production speeds and complex assembly processes.

✧ Broad ambient temperature applicability – Specific grades are engineered to perform reliably in ambient temperatures from 0°C to 43°C, ensuring consistent processing year-round and across climate zones.

✧ Optimized viscosity profile – Offers stable viscosity values between 5,000–10,000 mPa·s at 130°C, ensuring excellent wetting and flow characteristics on both porous and non-porous substrates.

✧ High-temperature resistance – Developed to maintain bond integrity under elevated temperatures, making it suitable for post-processing environments and demanding end-use conditions.

✧ Exceptional substrate compatibility – Demonstrates strong adhesion to a wide range of materials including MDF, wood veneers, PET films, acrylics, aluminum, SPC, and carbon crystal panels.

✧ Superior aging and durability performance – Resists yellowing and degradation over time, ensuring long-term structural and aesthetic integrity in architectural and interior applications.

✧ High-yield application efficiency – Formulated for optimal spread rate and minimal waste, supporting cost-effective manufacturing with high production output.

|

Parameter |

Typical Value |

Unit |

Notes |

|

Appearance |

Colorless and transparent |

– |

Visual inspection |

|

Solid Content |

43-47 |

% |

Can be adjusted for formulation |

|

Viscosity (25°C, Brookfield RV) |

5000-10000CPS (25 ℃) |

mPa·s |

Spindle 3, 20 rpm |

|

Color |

<1 # (Fe-Co) |

/ |

/ |

|

Density (25°C) |

1.05–1.15 |

g/cm³ |

Typical value |

|

Recommended Solvents |

Water |

– |

For formulation compatibility |

|

Shelf Life |

12 |

months |

Stored in sealed containers at 5–35°C |

|

Storage |

Cool, dry place |

– |

Avoid direct sunlight and moisture |

| Product Category | Model | Ambient Temp. (°C) | Viscosity (mPa·s / °C) | Application Temp. (°C) | Open Time / 25°C |

Key Characteristics | Suitable Substrates |

| PUR Flat Laminating Adhesive | YKM8602 | 20 - 43 | 6000 - 10000 / 130°C | 110℃-140℃ | 8 - 15 min | Wide application range, good high-temperature resistance | MDF, Decorative Panels, Acrylic Sheets, Aluminum Panels, SPC Panels, Carbon Crystal Panels, etc. |

| YKM8608 | 18 - 38 | 6000 - 10000 / 130°C | 110℃-140℃ | 4 - 6 min | Good aging resistance, high yield, particularly effective for PET | Wood Veneers, PET Lamination, etc. | |

| YKM8607 | 0 - 23 | 6000 - 10000 / 130°C | 110℃-140℃ | 15 - 25 min | Good low-temperature performance, high yield, particularly effective for PET | Wood Veneers, PET Lamination, etc. | |

| YKM8611 | 15 - 35 | 5000 - 9000 / 130°C | 110℃-140℃ | 20 - 30 min | Wide application range, good aging resistance, high yield | MDF, Decorative Panels, Acrylic Sheets, Aluminum Panels, SPC Panels, Carbon Crystal Panels, etc. | |

| YKM8613 | 25 - 40 | 5000 - 9000 / 130°C | 110℃-140℃ | 10 - 20 min | Wide application range, good aging resistance | MDF, Decorative Panels, Acrylic Sheets, Aluminum Panels, SPC Panels, Carbon Crystal Panels, etc. |

Applications

Our thermally activated, moisture-curing polyurethane (PUR) hot melt adhesives are engineered for high-performance bonding across a broad spectrum of decorative and industrial laminating applications. These adhesives deliver robust durability, thermal resistance, and superior substrate compatibility, meeting stringent international standards for quality and performance.

◊ Decorative flat lamination on engineered wood panels – Provides strong, durable bonds for MDF, particleboard, and multi-density fiberboards used in furniture, cabinetry, and interior cladding

◊ PET film lamination onto wood-based substrates – Specially formulated variants (e.g., YKM8608, YKM8607) ensure high yield and excellent adhesion in high-speed finishing processes

◊ Metal composite material (ACM) bonding – Suitable for laminating aluminum and other metal sheets to core materials in architectural panel production

◊ Rigid plastic panel lamination – Bonds acrylic, SPC (stone plastic composite), and carbon crystal panels with high heat and aging resistance

◊ Veneer and foiled panel production – Ensures consistent bonding performance across a range of open times (4–30 minutes) to accommodate varying line speeds and ambient conditions

◊ Low-temperature environment laminating operations – Certain grades (e.g., YKM8607) maintain viscosity and open time stability in challenging conditions down to 0°C

◊ High-temperature end-use applications – Delivers reliable performance in environments requiring thermal endurance, such as kitchen cabinets, bathroom fixtures, and exterior architectural elements

Benefits

Key Traits: Moisture-curing thermoset polyurethane hot melts; activated within 110–140°C application range; designed for varied ambient conditions (0–43°C); tunable open time (4–30 min)

✧Primary Benefits:

Enables strong covalent bonding through moisture-triggered crosslinking, ensuring durable and chemical-resistant joints

Wide operating temperature range accommodates seasonal or regional climate variations, improving process flexibility

Adjustable open time allows optimization for manual or automated production lines, increasing application precision and reducing waste

Excellent thermal and aging resistance ensures long-term performance under demanding environmental conditions

High-yield formulation offers superior spread rate and material efficiency, reducing overall product cost

✧Typical Uses:

Furniture and cabinet manufacturing: Bonds wood veneers, PET films, and decorative panels to MDF with high heat and moisture resistance

Architectural interior panels: Laminates acrylic, aluminum, and SPC substrates for wall cladding and decorative systems

Flooring composites: Provides durable bonding for carbon crystal panels and engineered flooring components

Industrial laminate production: Suitable for continuous roll-to-roll or platen-based pressing processes

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :