PUR Adhesive is a high-performance adhesive that combines the instant setting of hot melts with the ultimate strength and durability of structural adhesives. It cures upon exposure to atmospheric moisture, forming permanent, resistant bonds that withstand extreme stress, temperature, and environmental conditions. Ideal for demanding industries like furniture, automotive, and packaging, PUR offers unparalleled performance for laminating, wrapping, and edge-banding applications.

Item No :

PUR Heat Pressure AdhesiveApplication :

Used in woodworking, electronics, auto, packaging, construction.Special Feature :

PUR adhesives offer high-temperature resistance, strong bonding, and durability for diverse substrates.--------------占位---------------

Types of PUR adhesive

Application of PUR adhesive

This type of adhesive is primarily used for laminating various decorative surfaces onto substrate materials such as MDF, acrylic boards, aluminum plates, SPC panels, and carbon crystal boards. It offers excellent high-temperature resistance and a broad application range, making it a versatile hot-melt adhesive for flat lamination processes. The reactive polyurethane adhesive ensures strong bonding and durability, suitable for both standard and PET film lamination applications.

This high-viscosity adhesive is designed for wrapping applications involving wood veneers, PET films, CPL materials, and high-rebound substrates. It provides strong initial tack, excellent adhesion, and resistance to blistering under heat. The moisture-curing adhesive is ideal for edge banding and surface wrapping processes, ensuring a reliable and durable finish even on challenging materials.

Specifically formulated for edge sealing applications, this thermoplastic reactive adhesive excels in both low-temperature and high-temperature environments. It prevents false adhesion in winter and offers high initial tack in summer, making it a versatile PUR hot-melt adhesive for various substrate materials. Its fast-setting properties and cost-effectiveness make it a preferred choice for furniture and panel edge banding.

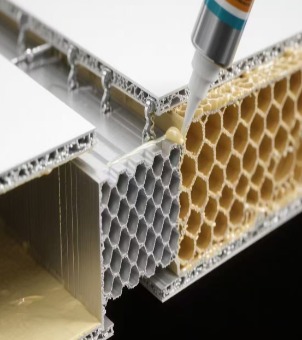

This structural adhesive is optimized for bonding honeycomb panels, including aluminum honeycomb structures. It provides high initial tack, excellent material breakage performance, and a wide operating temperature range. The reactive polyurethane hot-melt adhesive ensures robust and durable bonds, making it ideal for lightweight composite panel manufacturing and other industrial applications requiring strong structural integrity.

Ordinary Adhesives vs PUR Adhesive

| Feature | Ordinary Adhesives | PUR Adhesive | What This Means For You |

| Bond Strength | Good for basic bonds, often just surface level | Extremely High & Deep. Reacts with materials for a superior hold | Products are more durable & last longer. Say goodbye to things falling apart |

| Materials | Works on limited materials, often specific types | The "All-Rounder". Bonds wood, metal, plastics, glass, and more | Simplifies your work. No need for different glues for different materials. Saves storage and hassle |

| Resistance | Poor. Not resistant to water, heat, or chemicals | Excellent. Great water, heat, chemical, and temperature resistance | Products can be used in tough conditions like kitchens, bathrooms, or outdoors |

| Speed & Process | Slow drying/curing (hours to days). Ties up space and clamps | Sets initially in minutes for handling. Reaches full strength in days | Massively improves production speed. Frees up equipment and space. Your production line moves faster |

| Cleanup & Eco | Messy, can leave stains, hard to clean. Often contains solvents and strong smell | Clean & Eco-Friendly. Excess can be peeled off. Solvent-free, low odor | A cleaner finish, saving cleanup time. Better for worker health and the environment |

| Cost | Cheap per bottle, but you use more. Slow process hurts efficiency | Higher cost per bottle, but you use very little. Highly efficient | Lower total cost! While initial cost is higher, it saves you money, time, and effort in the long run |

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :