DTF Printed Film Coating: A precision-formulated, dual-layer polymer system engineered for flawless direct-to-film transfer. Its thermally-activated silicone release layer ensures clean separation, while the specialized hot-melt adhesive layer melts, flows, and permanently bonds to substrates upon cooling. This creates durable, high-fidelity graphics with exceptional wash and abrasion resistance on textiles and hard surfaces.

Item No :

Heat Transfer DTF film CoatingApplication :

Direct Transfer Film release layer and ink adsorption layerSpecial Feature :

This product offers cold and heat peel off,good ink dispersibility and adhesionProduct Overview

Runshine New Materials (Foshan) Co., Ltd. specializes in advanced Direct-to-Film (DTF) PET transfer coatings, a sophisticated multi-layer polymer system engineered for superior digital graphics transfer. Our coatings are formulated with a precision-engineered silicone-based release layer and a specialized thermoplastic adhesive layer.Upon application of heat and pressure, the coating system undergoes a controlled phase transition: the release layer facilitates a clean and precise separation from the PET film carrier, while the adhesive layer melts, flows, and wets the target substrate. Upon cooling, it solidifies through a physical curing process, forming a tough, flexible, and highly durable bond. This results in exceptional image fidelity, brilliant color vibrancy, and outstanding resistance to washing, abrasion, and chemicals.Ideal for demanding applications on textiles, plastics, metals, and ceramics, our DTF coatings ensure long-lasting performance for personalized apparel, promotional items, and industrial branding. We provide tailored coating solutions and comprehensive technical support to ensure optimal transfer efficiency and end-product reliability for specialized manufacturing needs.

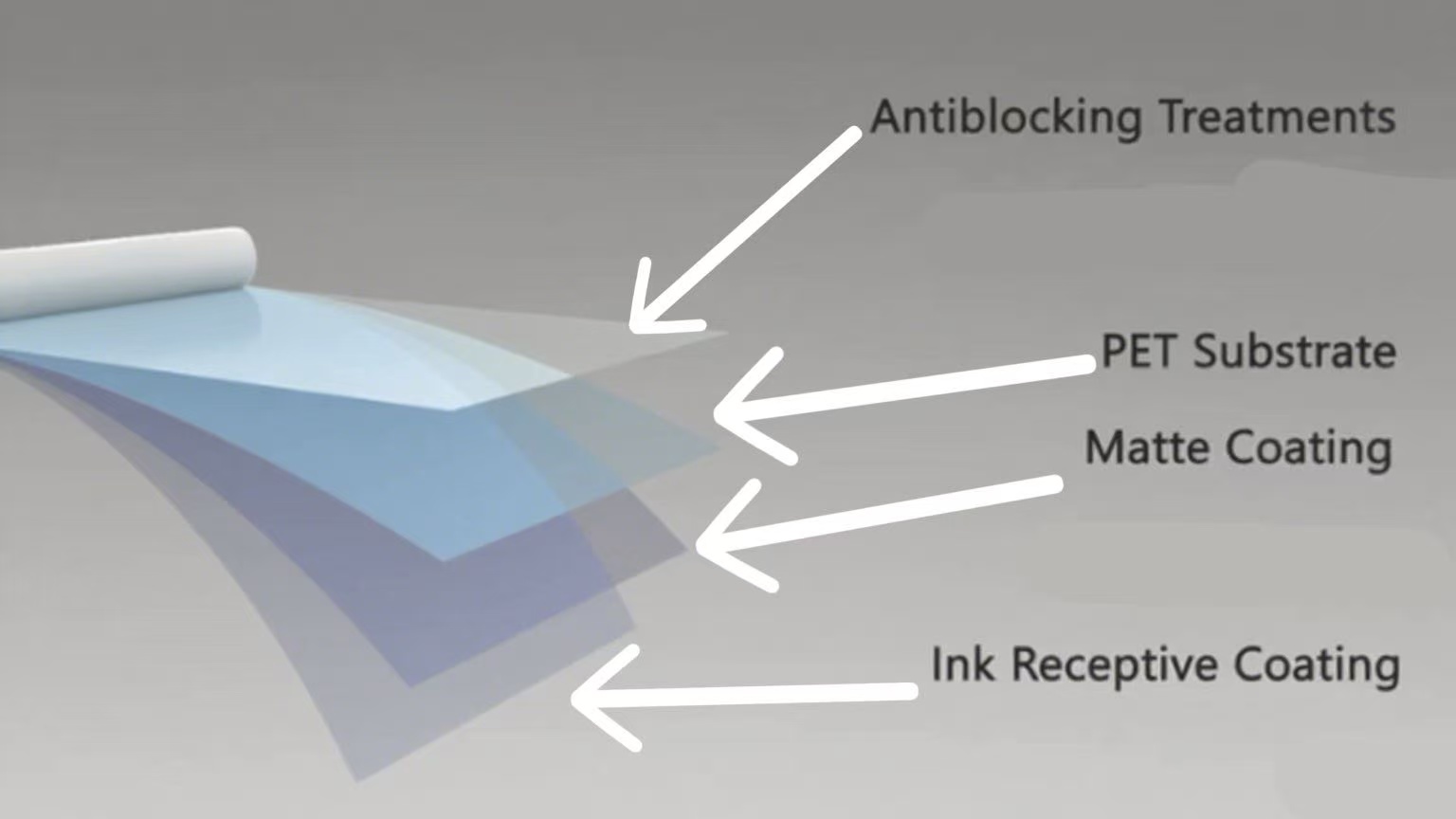

What is a DTF (Direct-to-Film) PET Coating?

A DTF (Direct-to-Film) PET coating is a multi-layer composite system comprising, sequentially, a polyester film substrate, a release layer, and an ink-receptive layer; the critical release layer is a cross-linked silicone polymer coating engineered for a clean and precise thermal separation from the film carrier due to its tailored low surface energy, while the specialized ink-receptive layer is formulated with porous polymers and absorbent pigments to rapidly capture and anchor inkjet pigment particles, ensuring sharp image formation and subsequent cohesive transfer of the entire printed film to the final substrate.

Release Layer

The release layer is a precisely engineered, thin-film coating typically formulated from a platinum-catalyzed addition-cure silicone system. This chemistry is selected for its ability to form a highly cross-linked, three-dimensional siloxane (Si-O-Si) network upon curing. This cured network provides exceptional thermal stability and controlled, predictable release performance. The fundamental operating principle is the establishment of a critical, low surface energy interface (typically between 20-24 mN/m), which minimizes adhesion to the subsequently applied ink film. During the heat press transfer, this layer undergoes a precise and controlled fracture at the interface between the silicone network and the topcoat, a phenomenon known as a cohesive release. This ensures the entire printed image separates cleanly and completely from the inert PET film carrier without silicone residue, enabling a full and consistent transfer to the substrate.

Ink Receptive Layer

The ink receptive layer is a complex, micro-porous composite coating designed for optimal dye-sublimation and pigment inkjet performance. Its formulation is based on a polymer matrix, commonly comprising polyvinyl alcohol (PVA) or polyurethane (PU) dispersions, which serves as a strong, flexible film-forming agent. Throughout this matrix, a high loading of nano- to micro-scale absorbent pigments, such as silica or alumina, is uniformly dispersed. This creates a high-surface-area, capillary network that acts via physio-sorption to instantaneously absorb ink solvents and mechanically trap pigment particles. This rapid dewatering prevents lateral ink bleeding, ensuring sharp dot reproduction and high color density. Crucially, this layer is engineered to possess a controlled adhesion to the underlying release layer; it must form a cohesive bond stronger than the release force of the silicone, allowing the entire ink layer to be lifted as a unified film during transfer and then subsequently bonded to the final substrate via a hot-melt adhesive mechanism.

Product introduction

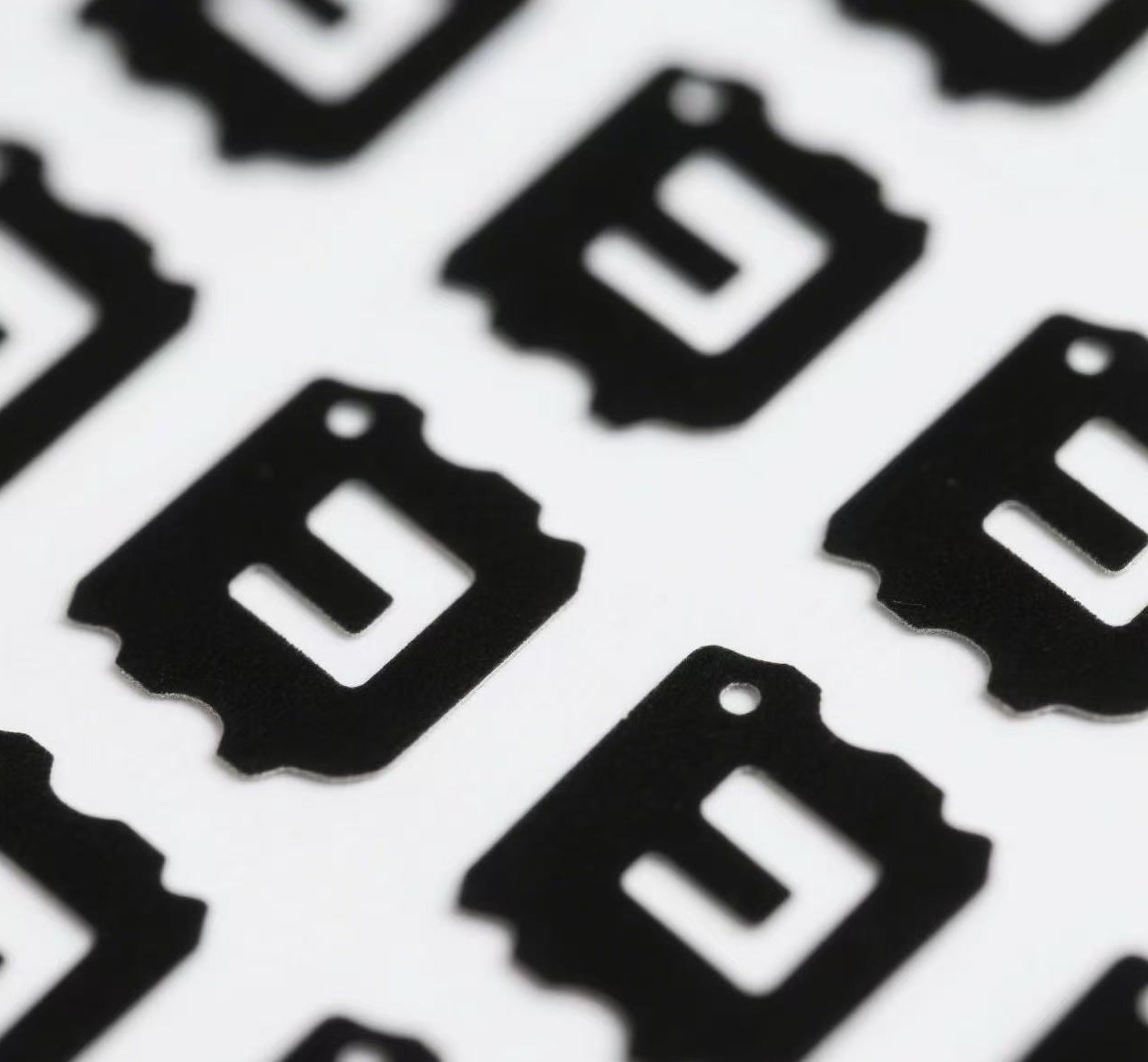

Our Direct-to-Film (DTF) PET transfer coatings deliver superior graphic transfer performance across a wide range of substrates and processing conditions, ensuring high-fidelity image reproduction, excellent wash and abrasion resistance, and reliable operation in both high-speed digital printing and demanding transfer environments. Designed for precision and durability, they provide sharp, bubble-free adhesion for textiles, promotional products, industrial labels, and personalized apparel applications, making them the ideal choice for advanced digital surface decoration solutions.

| Product | Appearance | Solids content (%Wt) | pH-value (25oC) pH value | Viscosity (25oC, Brookfield, mPa·s) |

| coat-516 | Milky white or light yellow liquid | 25±2 | 4.0 - 6.0 | <2500 |

| coat-529 | Milky White Or Light Yellow Liquid | 35±2 | 7.0 - 8.0 | <3500 |

Key Features

Coat-516: Water-Peelable Cationic Ink-Absorbing Coating

Coat-516 is a advanced water-peelable coating engineered with a cationic polymer matrix designed to facilitate efficient ink anchoring through electrostatic interaction and physical absorption. Its formulation ensures uniform wetting and rapid ink fixation, eliminating issues such as water edge (peripheral bleeding) during digital printing. The coating exhibits exceptional ink absorption capacity due to its micro-porous structure, which enhances color vibrancy and resolution by preventing pigment migration. Additionally, it offers superior release properties through a controlled cohesive release mechanism, allowing clean separation from the PET film without residue. The optimized mechanical properties further ensure precise cutting and handling stability, making it ideal for high-resolution graphics and textile transfer applications.

Coat-529: Free-Tear Water-Based Silicone Release Coating

Coat-529 is a solvent-resistant, water-based silicone release coating formulated with a cross-linked siloxane network that ensures robust adhesion on PET substrates. Its excellent surface wetting and covalent bonding with the PET film enhance interfacial stability, resisting delamination even under solvent exposure. The coating’s free-tear characteristic is achieved through tailored elasticity and fracture toughness, enabling smooth, controlled tearing without film fragmentation. The platinum-catalyzed silicone chemistry provides thermal stability and consistent release performance, while its water-based composition aligns with eco-friendly manufacturing standards. This coating is suitable for applications requiring durable release layers and resistance to aggressive chemical environments.

Applications

Engineered for industrial-grade graphic transfer, our Direct-to-Film (DTF) PET coatings deliver exceptional resistance to washing, abrasion, and chemical exposure, ensuring superior image durability and color fidelity on diverse substrates under demanding conditions.

Coat-516:

This coating is specifically formulated for applications requiring high-definition image transfer and efficient post-processing. Its cationic nature and optimized rheological profile (viscosity <2500 mPa·s) make it ideal for:

Digital textile printing via Direct-to-Film (DTF) transfer, ensuring vibrant color reproduction and sharp edges on polyester blends and nylon.

Peelable temporary graphics for promotional items and apparel, leveraging its water-redispersible mechanism for clean removal without residue.

Precision-cut decals and labels, where its balanced solids content (25±2%) facilitates uniform film formation and mechanical die-cutting performance.

Coat-529:

Designed for release liner and surface protection applications, this silicone-based coating exhibits robust chemical and physical properties:

High-performance release liners for adhesive tapes and graphic films, utilizing its solvent resistance and controlled tear properties (free-tear characteristic) to ensure smooth, consistent delamination.

Solvent-resistant barrier coatings on PET substrates in industrial packaging, where its adhesion (5B ASTM D3359) and cross-linked silicone network prevent migration of plasticizers or oils.

Thermal transfer carrier films requiring controlled release force and dimensional stability, supported by its higher solids content (35±2%) and neutral pH (7.0-8.0) for compatibility with sensitive adhesives.

Description of DTF Release Mechanisms

The release mechanism in Direct-to-Film (DTF) transfer is a critically engineered interface phenomenon governed by the viscoelastic properties and chemical composition of the silicone-based release layer. The differentiation between "cold," "warm," "second," and "hot" peel is defined by the temperature at which the printed PET film is separated from the transferred graphic, which directly correlates to the state of the thermoplastic adhesive layer and the release kinetics of the silicone coating.

Cold Peel:

The transfer is separated after the assembly has completely cooled to ambient temperature (typically below 30°C). At this stage, the thermoplastic adhesive has fully crystallized and achieved its final cohesive strength. The silicone release layer, designed for a high degree of cross-linking, requires a higher, sharper peel force. Fracture occurs cohesively within the release coating or at its interface, resulting in a crisp, clean release. This method is often used for applications requiring very precise, rigid graphics.

Warm Peel :

The transfer is separated while the assembly is still warm but not hot (typically between 40-60°C). The adhesive layer is in a partially crystalline, rubbery state, offering moderate green strength. The release layer's siloxane network is more compliant at this temperature, allowing for a smoother, lower-force peel with a excellent balance between ease of handling and graphic integrity.

Second Peel :

This refers to a separation occurring within a very short, specific time window (e.g., 5-15 seconds) after the heat press opens, while the adhesive is still in a semi-molten, high-elasticity state. It requires a release coating formulated for an extremely precise and rapid change in release force as temperature drops. This demands exceptional control over the silicone's cross-link density and surface energy to prevent tearing of the delicate ink film.

Hot Peel :

The transfer is separated immediately after the heat press cycle is complete, while the entire structure is still at an elevated temperature (typically >80°C). The thermoplastic adhesive is fully molten and has very low viscosity and cohesion. The release coating must be designed to exhibit a very low and consistent release force at high temperature, allowing the graphic to be cleanly lifted from the film carrier before the adhesive solidifies. This is a high-speed process demanding excellent thermal stability from the silicone polymer.

Our Product Capability:

Our DTF PET transfer coating system is engineered for unparalleled versatility. Through advanced silicone chemistry and precise control over polymer cross-linking and adhesion promotion, our product is uniquely formulated to perform reliably across all four release modalities: Cold, Warm, Second, and Hot Peel.This allows our customers to select the optimal peeling method for their specific production requirements, whether prioritizing high-speed operation (Hot Peel), ease of handling (Warm Peel), or maximum graphic precision (Cold Peel), all with a single, high-performance product.

Storage and remarks

Inthe case of intact onginal packaging, coat516 can be stored at20 'c for3 manhs afer dlivem.Therecommended storage iemperaure range is 5 'c 30c, frozenor the temperature exceeds 30 "c, it may affect the viscosity and average paricle size ofthe product and may eventualy cause precipitation orIf contaminated by bacteria, fungi or algae, it will cause irreversible damage to the product

The above infomalonis based an god fath and ourunderstanding ofthe produc athe ime of pubishing.Buyers are advised to verfy thesuabilty and salety ofthe produc aconding to actual needsWe reserve the right to make changes to the above information without prior notice.

General Application Instructions for Direct-to-Film (DTF) PET Transfer Coatings

1.Substrate Preparation:

The target substrate surface must be clean, dry, and free from dust, oil, mold release agents, or any other contaminants that could interfere with adhesion. For non-porous substrates (e.g., plastics, coated metals), surface activation via corona, flame, or plasma treatment is recommended to increase surface energy and ensure optimal wetting and bonding. Porous substrates such as textiles should be pre-treated to minimize fiber raise and ensure a smooth transfer interface.

2.Coating Application and Drying:

The aqueous coating dispersion must be applied uniformly using a precision Meyer rod, gravure, or slot-die coater. The applied wet layer should be dried immediately in a forced-air oven at 60–80°C to remove water and prevent premature migration of coating components. Incomplete drying may result in poor ink acceptance or reduced release performance. The dried coating should form a continuous, defect-free film with a target coat weight of 5–8 g/m² for the ink-receptive layer and 0.8–1.2 g/m² for the release layer.

3.Printing and Curing:

Pigment-based inkjet inks should be applied using calibrated piezoelectric printheads. After printing, the ink must be fully cured using infrared or forced-air drying (100–120°C) to evaporate water and coalesce the ink film. Incomplete curing will lead to poor transfer efficiency and reduced wash fastness.

4.Transfer Process:

Heat and pressure must be applied uniformly using a calibrated heat press. Typical transfer conditions are 150–160°C, 0.3–0.5 MPa, and 8–12 seconds. The silicone-based release layer undergoes controlled cleavage under heat, allowing the entire printed film to cleanly separate from the PET carrier and adhere to the target substrate through the thermoplastic adhesive layer.

5.Post-Transfer Conditioning:

After transfer, the decorated substrate should be conditioned at room temperature for 2–4 hours to allow the adhesive layer to fully crystallize and develop ultimate adhesion and wash resistance. For textiles, a post-cure at 150°C for 1–2 minutes is recommended to further cross-link the adhesive and enhance durability.

Important Safety and Handling Precautions for PUR Hot Melt Adhesives

1.Aqueous Coating Sensitivity:

DTF coatings are water-based dispersions and are sensitive to freezing and microbial growth. Store in original sealed containers between 5-30°C. Freezing will cause irreversible coagulation of polymer particles and pigment settling, while prolonged high-temperature exposure may lead to premature hydrolysis or microbial degradation, reducing coating performance.

2.Drying and Thermal Management:

Dry applied coatings immediately using forced-air ovens at 60-80°C. Incomplete drying will result in poor film formation and reduced ink adhesion. Avoid exceeding 100°C during drying, as this may cause premature cross-linking in the release layer or degradation of absorbent polymers, compromising transfer performance.

3.Dust and Particulate Control:

Coatings contain nano/micro-scale pigments and polymers. During handling and powder recovery, use NIOSH-approved N95 masks to avoid inhalation of airborne particles. Ensure adequate local exhaust ventilation in coating and drying areas to maintain airborne particulate levels below OSHA PEL limits.

4.Skin and Eye Protection:

While cured coatings are inert, liquid coatings may contain surfactants and organic acids (pH 4-6). Wear chemical-resistant gloves and safety goggles when handling concentrated products. In case of contact, flush immediately with plenty of water for at least 15 minutes.

5.Equipment Cleaning and Maintenance:

Clean application equipment immediately after use with warm water (40-50°C) before coatings dry. Dried coating residues require specialized alkaline cleaners (pH 9-11) for removal. Never use strong solvents that may damage precision coating equipment or leave contaminating residues.

6.Substrate Compatibility Testing:

Always test coating adhesion and release performance on specific substrate batches. Surface energy, porosity, and chemical composition variations may require adjustments in coating formulation, application weight, or transfer parameters to ensure optimal performance.

7.Curing and Performance Development:

Final adhesion and wash resistance develop through physical film formation and crystallization of polymer components. Allow transferred graphics to condition at room temperature for 2-4 hours before subjecting to mechanical stress or wash testing. Full durability is achieved after 24 hours of maturation at 20-30°C and 40-60% RH.

Sitemap Blog Xml Privacy Policy

Copyright @ Runshine New Materials(FoShan) Co.,Ltd. All Rights Reserved.

Network Supported

Network Supported

leave a message

Scan to wechat :

Scan to whatsapp :